Product introduction:

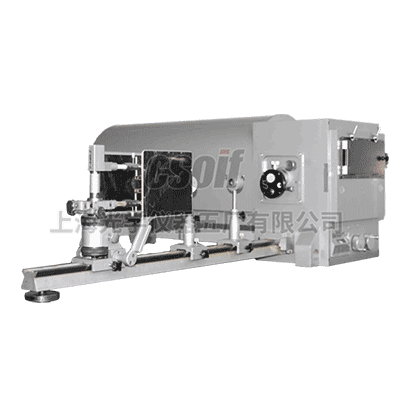

Mounting is a very important link in the preparation of metallographic samples, especially for some small samples that are not easy to handle, irregular shapes that need to protect the edges or samples that need to be automatically ground and polished. The mosaic is an essential process. YZXQ-2 automatic inlaying machine is an advanced hydraulic water-cooled automatic sample inlaying equipment. The inlaying process is controlled by the program, which realizes one-key operation of the inlaying process of heating, pressurization, pressure maintaining, cooling, and pressure relief. , without operator on-duty, automatically completes the sample inlay, and has the function of sound and light alarm. The machine is pressurized by a hydraulic pump, the pressure is higher, and the inlaid sample is more compact; the unique cold and heat separation design makes the operation safer and more stable; the high-definition touch screen display and control, real-time display of pressure and temperature, the inlaid plan can be saved, and it is easy to retrieve; Equipped with a water cooling system, the sample preparation speed is fast, and the unique rotary lock design is used for more convenient operation and stable performance. It is an ideal equipment for sample mounting.

The main parameters:

| model | YZXQ-2 |

Die Sleeve Specifications | Ф25mm, Ф30mm, Ф40mm (optional) |

Cavity height | 108mm, effective height 60mm |

heating power | Ф25mm/Ф30mm 1.8kW; Ф40mm 2.4kW |

pressurized pressure | Factory setting 150bar (equivalent to 15Mpa, 150kgf/cm2, not adjustable) |

Heating setting range | 50~180℃ (factory setting 120℃) |

heating time | User-defined 1~7 minutes (factory setting 3 minutes and 30 seconds) |

compress time | User-defined 30 seconds to 7 minutes (factory setting 1 minute) |

cooldown | User-defined 1 minute ~ 30 minutes (factory setting 2 minutes) |

total mosaic time | Ф30 specification about 6 minutes and 30 seconds |

cooling method | External water cooling |

input power | Single-phase 220V, 50Hz, 10A |

Dimensions | 520×480×520mm |

net weight | 60Kg |

The standard configuration:

| name | Specification | quantity |

host |

| 1 set |

Rotary handle |

| 1 |

upper module |

| 1 (already placed in the cavity) |

Oil pump breathing cover |

| 1 |

water inlet pipe | washing machine water inlet pipe | 1 |

outlet pipe | Ф10mm | 1 |

water inlet filter |

| 1 |

clamp |

| 1 |

mosaic powder | 500g | 1 bottle |

measuring cup |

| 1 |

funnel |

| 1 |

Product Manual |

| 1 serving |

certificate |

| 1 serving |

Options/Consumables:

| name | Specification |

Thermosetting inlays | black, white, red, green |

thermoplastic inlay | Transparent |

conductive inlay | black |

Custom Circulating Cooling Systems |

|