use:

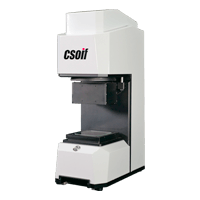

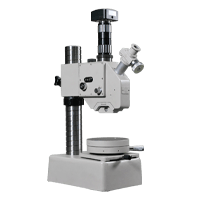

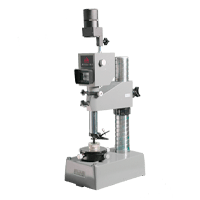

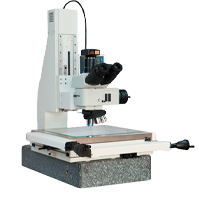

The 19JPC microcomputer type universal tool microscope is a classic measuring and testing instrument that our company has been producing for decades. The application of computer-aided measurement can solve various complex two-dimensional measurement requirements. The traditional Wan Gong display requires tedious measurements and complex calculations for geometric elements that cannot be directly observed in the field of view, such as the center of the circle, the midpoint, the intersection, the center line and its mutual distance, angle, etc., while in the 19JPC instrument All the above can be solved. The instrument uses precision grating sensors, PC series computers and data interfaces to collect measurement data, uses two-dimensional measurement software for data processing, and automatically calculates, instantly reads, or prints files to output measurement results. At the same time, the two-dimensional plane measurement element graphics can be easily converted to AutoCAD, and directly edited into the design drawings of the measured workpiece. The instrument is easy to operate. According to the graphic buttons or menu displayed on the screen, you can enter the measurement command to measure. During the measurement process of the instrument, the workpiece coordinates of the aiming point can be displayed in real time on the computer monitor screen, and the Cartesian coordinates or polar coordinates can be converted at any time, which is particularly convenient for polar coordinate measurement and cam measurement. The instrument uses both metric and imperial units of measurement. The calculation accuracy is 0.0001 mm and 0.00001 inch respectively. The instrument can automatically correct the assembly error of the slide guide rail of the worktable, which further improves the measurement accuracy.

Instrument features:

The computer type universal tool microscope 19JPC uses computer technology to process the measurement data on the basis of the traditional digital universal tool microscope 19JC. The composability and developability of the software enhance the function of the system and meet the needs of the vast number of users in a wider range. Microcomputer-type universal tool microscope is a multi-purpose measuring instrument widely used in machinery, electronic manufacturing, measurement and testing institutes, institutes, and universities and colleges and universities. It can be used to measure the size, shape, angle and position of any part within the range. And has two sets of reading systems (computer and digital display).

Typical measurement objects:

Measure the shape of various formed parts such as templates, template turning tools, template milling cutters, dies and cams.

Measure the pitch diameter, minor diameter, pitch, and half angle of the external thread (thread plug gauge, screw and worm, etc.).

Measure the lead, profile and profile angle of gear hob.

Measure the position of the holes on the circuit board, the drilling die or the orifice plate, the symmetry of the keyway and other shape and position errors.

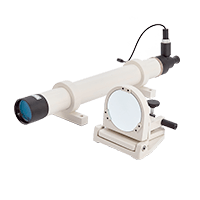

The main microscope is equipped with a variety of eyepieces and objective lenses, with a large field of view and clear imaging.

Adopt photoelectric digital display technology and use precision grating ruler as measuring element. Using advanced computer technology, the length signal collected by the grating digital display system is input into the computer in real time, and the data is processed by the special two-dimensional measurement software, and the results or graphics are printed or converted into AutoCAD drawings. The results are accurate and efficient.

The main microscope can be tilted left and right for the measurement of spiral parts.

Using non-contact or contact measurement as the basic method, through and reflected illumination can inspect parts with complex geometric shapes.

The accessories are complete and widely used.

Instrument completeness:

1. Host: digital universal tool microscope 19JC2. 2D measurement software

3. Branded commercial desktop computers and HP color inkjet printers

2D measurement computer operating system (software)

The main function

1. Basic measurement function: using WINDOWS interface, all operations are controlled by the mouse, which can measure points, lines, circles, arcs, angles, straightness, roundness, gears, threads, cams, etc.

2. Calculation function: After the measurement process is over, the outline of the workpiece is displayed on the computer screen, and all kinds of calculation and evaluation are completed by the mouse.

3. Graphic editing function: You can modify the contour of the workpiece to generate a new contour.

4. Printing function: All measurement results, calculation results and workpiece contours are saved in the computer in the form of files, which can be recalled, edited and printed at any time.

5. CAD interface: AUTOCAD can be called through the CAD interface, making full use of the functions of AUTOCAD.

Main technical specifications of universal tool microscope

1. Measuring range and division value

| X, Y coordinates | Measuring range: | 200×100㎜ | Resolution: 0.0001㎜ |

| Sight | Lifting stroke: | 120㎜ | |

| Arm tilt range: | 15 degrees left and right | Graduation value: 10′ | |

| Illumination diaphragm adjustment range: | φ3~φ32㎜ | Grid value: 1㎜ | |

| goniometer eyepiece | Angle measurement range: | 360° | Graduation value: 1′ |

| Contour eyepiece | Angle measurement range: | ±7° | Graduation value: 10′ |

| Arc reticle: | Radius of curvature: | R0.1~100㎜ | |

| Threaded reticle: | common thread pitch | t = 0.25 – 6㎜ | |

| Trapezoidal thread pitch | t = 2~20㎜ | ||

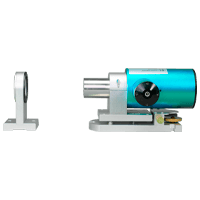

| Optical indexing head | Measuring range: | 360° | Graduation value: 1′ |

| Optical Positioner | Probe diameter: | Φ3±0.1㎜ (the limit verification error of the actual diameter value is not more than 0.5μm) | |

| Measuring force: | 0.1±0.03N | ||

| Maximum measuring depth | 15㎜ | ||

| glass workbench | Glass table size: | 215×130㎜ (Dimensions: 268×225㎜) | |

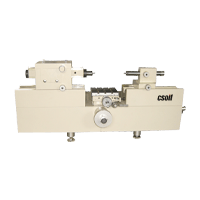

| Thimble holder | Maximum clamping diameter: | Φ100㎜ | |

| Maximum clamping length: | When the diameter of the tested piece is ≤55㎜: 750㎜ | ||

| When the diameter of the test piece is greater than 55mm: 600mm | |||

| High thimble holder | Maximum clamping diameter: | Φ180㎜ | |

| Maximum clamping length: | 600㎜ | ||

| V-shaped frame | Left V-shaped frame front and rear adjustment range: | 5mm each | |

| Right V-shaped frame height adjustment range: | 向上15㎜;向下3㎜ | ||

| Maximum load 40kg | |||

2. Aiming microscope optical parameters

| Objective lens magnification flag value | 1× | 3× | 5× | |

| total magnification | with goniometric or profile eyepieces | 10× | 30× | 50× |

| with dual vision eyepieces | 15× | 42× | 65× | |

| object field of view

(㎜) |

with goniometric or profile eyepieces | φ20 | φ6.6 | φ4 |

| with dual vision eyepieces | φ13 | φ4.7 | φ3 | |

| working distance

(㎜) |

with goniometric or profile eyepieces | 81 | 90 | 65 |

| with dual vision eyepieces | 47 | 85 | 63 | |

3. Instrument accuracy

Temperature requirements ⑴The temperature of the working room should be 20±1℃ ⑵The temperature change of the working room should be ≤0.5℃ per hour ⑶The temperature difference between the tested part and the instrument should be ≤0.5℃

Under the condition that the specified temperature requirements are met, the instrument has the following guarantees:

①When the X and Y coordinates are verified with a glass scale, the maximum inaccuracy of the instrument: (1 + L / 100) μm where L = measurement length unit: mm

②The maximum inaccuracy of the angle measurement of the goniometer eyepiece: no more than 1′

③Double image eyepiece Instability of combined image: no more than 0.0005mm Incorrect degree of combined image: no more than 0.001mm

④Maximum inaccuracy of optical indexing head: no more than 30″

⑤ Optical positioner Measurement instability: no more than 0.001mm, measurement inaccuracy: no more than 0.0015mm

4. Instrument weight and dimensions

Host net weight: 250㎏

Dimensions (l×b×h) mm: 980×1020×640