Features and uses:

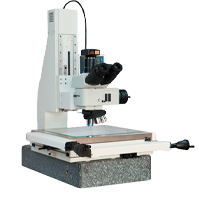

Metallographic microscopes are used to identify and analyze the structure of various metals, alloy materials and non-metallic materials, and are widely used in factories or laboratories for raw material inspection; casting quality identification or metallographic structure analysis after material processing; and surface cracks It is the metallographic analysis of steel, non-ferrous metal materials, castings and coatings; the petrographic analysis of geology; and the effective means of microscopic research on compounds and ceramics in the industrial field. It is an essential instrument for studying the organizational structure of materials in materials science, and it is also a right-hand man in the field of scientific research and teaching.

More and more studies are no longer satisfied with the conventional metallographic microscopy and photography methods. Microscopic imaging is input into the microcomputer, and the microprocessor performs various post-processing on the image. It is a new technology in the field of microscopy that is synchronized with the world today.

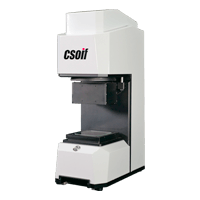

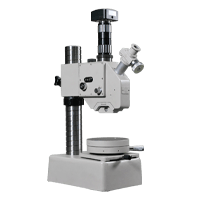

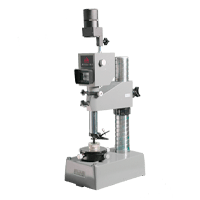

The 4XC-MS image analysis metallographic microscope is equipped with a high-pixel digital photography system (or CCD camera), with multiple optical zooms, various magnifications can be selected continuously, and the images are processed, edited, saved and processed by the computer. Output (such as printing, etc.) or enter the multimedia system and e-mail.

The system can be equipped with “professional quantitative metallographic image analysis computer operating system” (software) to conduct real-time research and analysis on metallographic patterns, such as grain size measurement and rating; non-metallic inclusion measurement and rating; pearlite and ferrite content The measurement rating of ductile iron; the measurement and rating of the graphite nodularity rate of ductile iron; the analysis, statistics and output of graphic reports of decarburization layer, carburized layer measurement, surface coating thickness measurement, etc.

technical parameter:

1. Structure: Inverted trinocular tube, 30° inclination, adjustable interpupillary distance and diopter, 4 nosepieces

2. Total magnification: microscope 100-1000×image 300-3000×

3. Double-layer mechanical stage: 200 × 152 mm, moving range 15 × 15 mm

4. Focusing mechanism: Coaxial coarse and fine movement Limit protection Lifting range 30 mm Fine adjustment 0.002 mm

5. Lighting system: Brightness adjustable halogen lamp 20W/6V with color filter

6. Magnification and field of view (other magnifications can be selected)

Instrument completeness

(1) The main body of the instrument

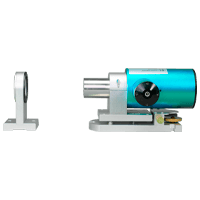

⑵ Light source group

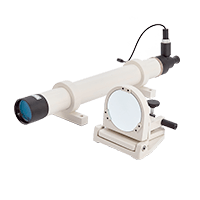

⑶ Eyepiece tube

⑷ Trinocular interface

⑸ Plan objective PL10×, PL20×, PL40×, PL100× oil

⑹ Flat field eyepiece 10×

⑺ color filter yellow, green, blue, frosted

⑻ Synthetic immersion oil

⑼ Slide Φ10 mm, Φ20 mm

⑽ Dust cover

⑾ Elastic clip

⑿ Spare bulb 20W/ 6V

⒀ Spare fuse 0.5A

System Configuration

1. Metallographic microscope: Trinocular inverted metallographic microscope 4XC

2. Digital Adapter Lens: Optical and mechanical interface between special microscope and CCD camera

3. Color CCD camera

4. Image processing system: dedicated image capture card (high-resolution image real-time capture card secondary development software package)

5. Image analysis system: professional quantitative metallographic analysis computer operating system (software)

6. Microcomputer and printer: Lenovo commercial computer and brand printer (current mainstream configuration)

image processing system

Dedicated image capture card that can transmit digital video signals to display memory or system memory in real time. The input color video signal is processed by digital decoder, analog/digital converter, scaling, cropping, color space conversion, etc., and is displayed in real time through PCI bus to VGA card or transmitted to computer memory for real-time storage. The data transmission process is controlled by the image card without CPU participation, and the instantaneous transmission speed can reach 132MB/S.

The system has the following characteristics:

Input mode: Software selection and switching: six-way CVBS input, three-way Y/C input, six-way analog video output;

Image acquisition resolution: 768×576×24bit (PAL), 640×480×24bit (NTSC);

Flexible image acquisition: Supports multiple acquisition methods such as single field (odd field or even field), single frame, continuous field, continuous frame, interval several fields or several frames;

Graphic overlay function: By filling in the mask (MASK) template, the input image of any shape can be displayed and stored in real time;

The hardware completes the scaling (SCALE) and cropping (CLIP) of the input image; the size and position of the input image can be set flexibly;

Support chromaticity space conversion YUV4:2:2, RGB32 and Y8Bit and other image display and storage formats;

Support the working mode of displaying the computer content and the collected images on the same screen;

Support software to adjust brightness, hue, color saturation, contrast;

Support user encryption function: protect user software from piracy;

Provide development tools and demonstration programs in WINS and Linux environments; support VC, VB, BC, C++ Builder and other development environments.

Introduction of metallographic image analysis system (professional quantitative metallographic analysis software)

The metallographic image analysis system (software) integrates today’s advanced image analysis technology, which is the perfect combination of metallographic microscope and intelligent analysis technology. The measurement and rating results are fast and accurate, and conform to the national standard and the American ASTM standard. The system interface is all finished in Chinese, which is concise, clear and easy to operate. After simple training or referring to the instruction manual, it can be operated freely.

The system includes the following functions:

Image editing software: more than ten functions such as image acquisition and image storage;

Image software: more than ten functions such as image enhancement and image overlay;

Image measurement software: dozens of measurement functions such as perimeter, area, and percentage content;

Output mode: data table output, histogram output, image print output.

Dedicated metallographic software packages:

Grain size measurement and rating (grain boundary extraction, grain boundary reconstruction, single phase, dual phase, grain size measurement, rating);

Measurement and rating of non-metallic inclusions (including sulfides, oxides, silicates, etc.);

Pearlite and ferrite content measurement and rating; ductile iron graphite nodularity measurement and rating;

Decarburization layer, carburized layer measurement, surface coating thickness measurement;

Phase-area measurement of ferritic and austenitic stainless steels;

Analysis of primary silicon and eutectic silicon of high silicon aluminum alloy;

Nearly 200 professional projects such as titanium alloy material analysis, meet the requirements of metallographic analysis and inspection of most units.