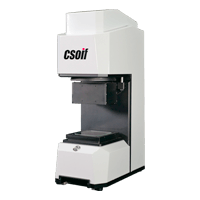

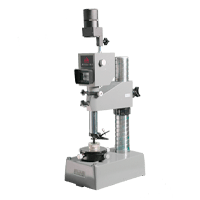

Features :

1. Equipped with precision sensors and CPU microcomputer control system, can automatically compensate, the test results are accurate and stable;

2, with 1Level 0 test force, which can test a wider range;

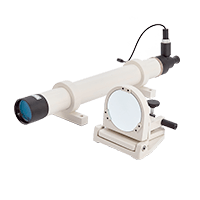

3. After measuring the indentation through the eyepiece, press the key to input the indentation length to directly obtain the hardness value, which improves work efficiency;

4. Equipped with a built-in printer, which can analyze and print the measurement data.

5. Equipped with high-performance stepper motor to automatically load and unload the test force, resulting in less noise during the test;

6. The shell is cast at one time, the structure is stable and not deformed, and it can work in a relatively harsh environment;

7. The surface is treated with car paint process, which has strong scratching ability and is still as bright as new after many years of use;

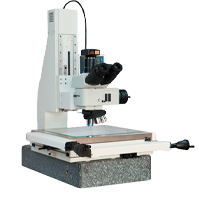

8. Brinell image measurement software is optional for this machine, which greatly improves work efficiency;

use:

It is suitable for hardness tester test of metal materials with large grains, which can reflect the comprehensive properties of materials;< span style=”font-family: arial, helvetica, sans-serif;”>cast iron, steel, non-ferrous metals, alloys especially for softer metals such as pure aluminum, lead, tin, etc.It can be used for the determination of the hardness of some non-metallic materials such as hard plastic and bakelite

technical parameters:

| Product Model | HBE-3000A | |||||

| Brinell scale | HBW2.5/62.5 | HBW2.5/187.5 | HBW5/62.5 | HBW5/125 | HBW5/250 | HBW5/750 |

| HBW10/100 | HBW10/250 | HBW10/500 | HBW10/1000 | HBW10/1500 | HBW10/3000 | |

| Test force | 62.5kgf(612.9N)100kgf(980.7N)125kgf(1226N)187.5kgf(1839N)250kgf(2452N)500kgf (4903N)750kgf(7355N)1000kgf(8907N)1500kgf(14710N)3000kgf(29420N) | |||||

| Load Control | Auto (load/hold/unload) | |||||

| Maximum specimen height | 220mm | |||||

| minimum unit of measure | 0.005mm | |||||

| Still time | 0~60s | |||||

| Hardness test range | 3.18~653HBW | |||||

| Total magnification | 20X | |||||

| Standard implementation | EN ISO 6506, , ASTM E-10-08, GB/T231.2, JJG150-2005 | |||||

| indenter-outer wall distance | 135mm | |||||

| indenter-upper wall distance | 55mm (the distance between the indenter and the upper machine wall can be increased by customizing the indenter)span> | |||||

| hardness read | After measuring the indentation through the eyepiece, press the key to input the indentation length to get the hardness value directly. | |||||

| Data output | Built-in printer, print content: test conditions, number of measurements, average value, maximum value, minimum value, maximum error, etc.< /span> | |||||

| power | AC220+5%,50~60Hz | |||||

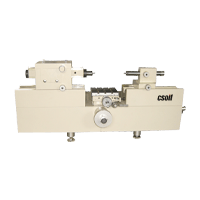

| Dimension (mm) | 520*210*745mm | |||||

| Host weight | about 120kg | |||||

Attachment:

| name | number | name | number | ||

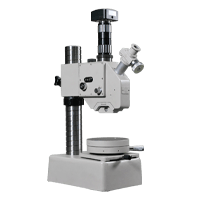

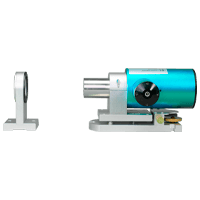

| Measuring microscope | 1 set | 2.5, 5, 10mm diameter carbide ball indenters | 1 of each | ||

| Standard hardness block | 3 blocks | Large, medium and V-shaped test benches | 1 each | ||