I. Purpose

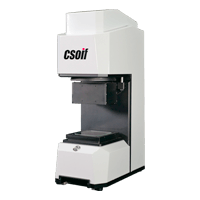

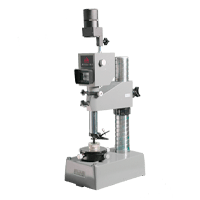

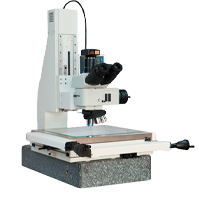

HBRV-187.5 Blowwell hardness tester is a multi-purpose and multi-functional hardness tester with three test methods of Brinell, Rockwell and Vickers and seven test forces, which can meet various hardness testing requirements of users. After the initial test force is manually loaded, the loading, holding and unloading of the total test force are automatically completed. It has a wide range of use and is easy to operate. It is a standing hardness tester for industrial and mining enterprises and scientific research institutions. Determination of Brinell, Vickers and Rockwell hardness of ferrous metals, non-ferrous metals and hard alloys: Brinell hardness of castings, annealed steel, normalized steel, non-ferrous metals and soft alloys; Rockwell hardness of quenched, quenched and tempered heat-treated materials Hardness; Vickers hardness of nitrided layer, ceramics, sheet, metal sheet, electroplating layer, tiny parts;

2. Features

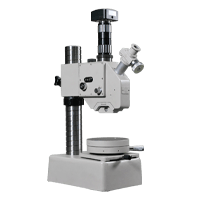

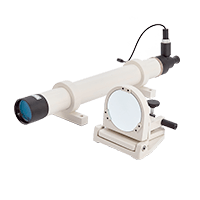

1. The optical system designed by the senior optical engineer not only has clear images, but also can be used as a simple microscope, with adjustable brightness, comfortable vision, and long-term operation is not easy to fatigue;

2. It has three test methods of Brinell, Rockwell and Vickers, and seven test force, which can meet various hardness test requirements;

3. The structure of the casting shell is stable and not deformed at one time, the pure white car paint is of high grade, and the scratch resistance is strong, and it is still bright as new after many years of use;

4. Our company has the ability to develop, design, produce and process by ourselves. Our machines provide parts replacement and maintenance and upgrade services for life;

Three, technical parameters

| Product number | HBRV-187.5 | ||||

| force | 30 -187.5kgf, level 7 test force | ||||

| Brinell scale | HB1/30, HB2.5/31.25, HB2.5/62.5, HB2.5/187.5, HB5/62.5, HB10/100 | ||||

| Brinell test force | 30, 31.25, 62.5, 100, 187.5Kgf (294.2, 306.5, 612.9, 980.7, 1839N) | ||||

| Rock Ruler | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HEP, HRR, HRS, HRV | ||||

| Rockwell test force | 60kgf(588N) 100kgf(980.7N) 150kgf(1471N) | ||||

| Vickers Scale | HV30 HV100 | ||||

| Vickers test force | 30kgf(294.2N) 100kgf(980.7N) | ||||

| objective lens | 2.5X Objective 5X Objective | ||||

| microscope magnification | Brinell: 37.5×, Vickers: 75× | ||||

| smallest unit of measure | Brinell: 0.004mm Vickers: 0.002mm | ||||

| Maximum test height | Rockwell: 230mm Brinell, Vickers: 180mm | ||||

| dwell time | 2~60s | ||||

| Hardness test range | Rockwell: 20~100 Vickers: 8~2900 Brinell: 3.18~653HBW | ||||

| power supply | AC220+5%, 50~60Hz | ||||

| Dimensions (mm) | 530*200*700 | ||||

| Host weight | 95kg | ||||

| name | quantity | name | quantity | |

| Rockwell diamond indenter | 1 | Rockwell 1.5875mm carbide indenter | 1 | |

| Vickers diamond indenter | 1 | Brinell 2.5mm carbide indenter | 1 | |

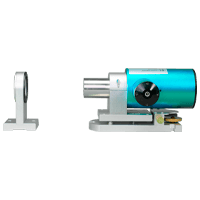

| Measuring microscope | 1 | flashlight | 1 set each | |

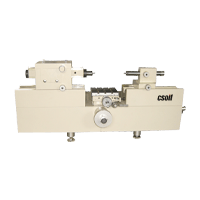

| Hardness block | 3 pieces | Medium and V-shaped test bench | 1 each | |

| power cable | 1 | Sliding test stand | 1 | |

| objective lens | 2 | Product Manual | 1 serving | |