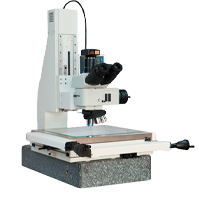

I. Purpose

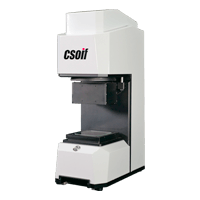

HBS-62.5Z digital display small load Brinell hardness tester is opto-mechatronics High-tech product, the machine has a novel shape , has good reliability and can Operability and intuitiveness, it is a new type of Brinell testing instrument using precision mechanical technology and optoelectronic technology. The machine adopts computer software programming and optical measurement system. Through soft key input, you can select different indenter and force value measurements, adjust the strength of the measurement light source, and select the dwell time. serif; text-indent: 24px; background-color: rgb(255, 255, 255);”>LCDThe indenter diameter, test force, measurement range, and hardness value can be read directly on the screen, which simplifies the tedious look-up table. It is easy to use, and the measurement accuracy is higher due to the use of a rotary encoder. Due to the large pressure used in the Brinell hardness test, the large ball diameter of the indenter and the large indentation diameter, it is suitable for the hardness measurement of metal materials with large grains. Such as cast iron, non-ferrous metals and their alloys, after various annealing and tempering treatments, and most of the steel delivered from the factory, this instrument selects the Brinell hardness value relative.< span style=”font-family: arial, helvetica, sans-serif; font-size: 16px;”>A smaller part, so it is especially suitable for softer metals, such as pure aluminum, copper, lead, tin, zinc, etc. and their alloys, and the measured hardness is accurate. The hardness has a high measurement accuracy, so the repeatability and representativeness are good. It is suitable for hardness test of metal materials with large grains, which can reflect the comprehensive properties of materials; cast iron, steel, non-ferrous metals, especially for softer metals, such as pure aluminum, lead, tin, etc.

two, characteristics

1, 4 inch large LCD display, menu structure,

2. The test process is automated and easy to operate

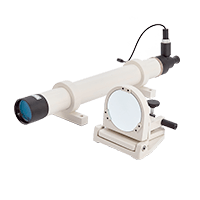

3. High-definition optical system The brightness of the light source can be adjusted in 20 levels.

4, with hardness value conversion function, hardness upper and lower tolerance judgment.

5. Diagonal length D1 and D2 encoder input to reduce human reading errors.< /span>

6. The objective lens and indenter can be automatically switched for accurate positioning.

7. Test results and data processing can be output by printer.

8, The shell is cast at one time, the structure is stable and not deformed, and it can be used in relatively Working in harsh environments;

9. The surface is treated with car paint process, which has strong scratching ability and is still bright after many years of use as new;

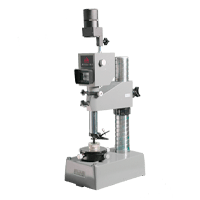

III. Technical parameters

| Product Model | HBS-62.5Z | ||||

| Test force | 1, 5, 10, 15.625, 30, 62.5kgf | ||||

| display | 5-digit hardness value, 4-digit diagonal length (D1, D2 ), hold time, number of tests, mean, standard deviation, return | ||||

| Test force holding time (s) | 1~99 | ||||

| loading controls | Auto (load/hold/unload) | ||||

| conversion ruler | Rockwell, Superficial Rockwell, Vickers | ||||

| minimum unit of measure | 0. 25μm (subject to the selected objective) | ||||

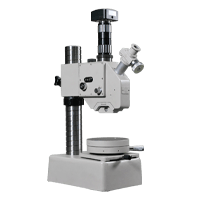

| Total magnification | Objective: Observe or measure 5

Measure 10X (special objective lens please order separately) Total magnification: 50X, 100X |

||||

| Data output | built-in printer | ||||

| Maximum specimen size | max height 165mm | ||||

| indenter center to inner wall | 130mm | ||||

| Standard implementation | Accuracy conforms to GB231.2, ISO6506-2 and ASTME10 | ||||

| power | AC220V±5%, 50~60Hz | ||||

| Instrument weight | about 45kg | ||||

| Standard Accessories Accessories | Objective lens 5x, 10x, Brinell indenter Φ1Φ2.5, Φ5 digital measuring eyepiece 10x , large flat test bench, medium flat test bench, V-shaped test bench, hardness block (2), power cord, etc. | ||||

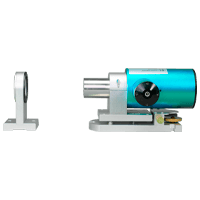

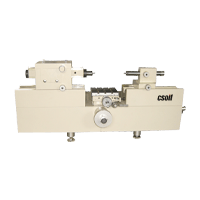

| Options | XY table, CCD measurement system | ||||

Attachment:

| name | quantity | name | quantity |

| Instrument host | 1 set | objectives 5x, 10x | 1 of each |

| Digital measuring eyepiece 10x | 1 | Brinell indenter Φ1Φ2.5Φ5 | 1 of each |

| Standard hardness block | 2 blocks | Large, medium and V-shaped test benches | 1 of each |

| Power cord | 1 root | Product certificate, product instruction manual | 1 copy of each |

| fuse | 2 | ||

| Options | XY table, CCD measurement system. | ||