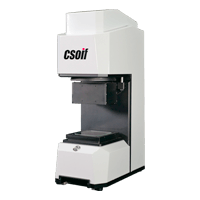

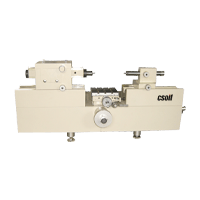

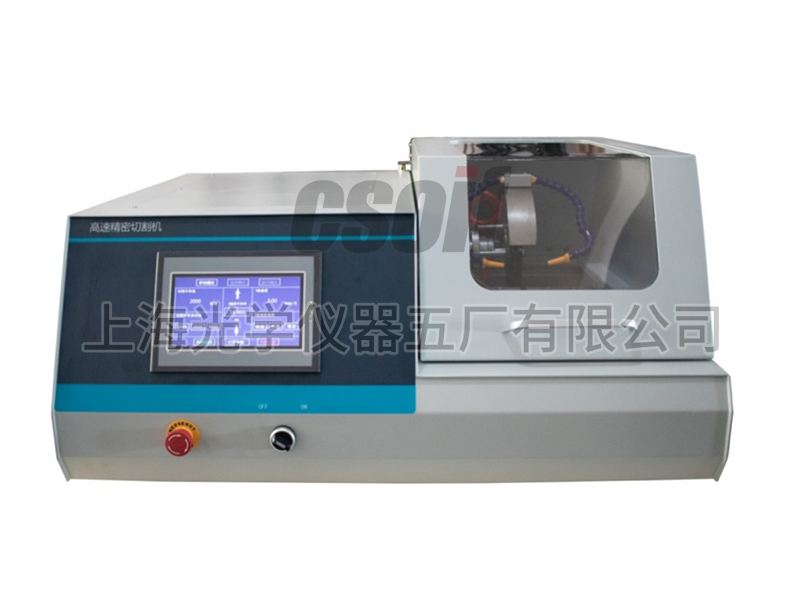

1.product overview

In the process of metallographic sample preparation, the first important process of sample preparation when the sample material is cut, HQG-100 shell structure, and accompanied by a cooling water tank, can make the configured coolant for recycling, in order to extend the service life of the equipment and operation and maintenance convenience, The main parts of the machine, such as the inner cover shell, the wheel shaft sleeve, the jaws and the workbench, are made of corrosion-resistant materials, which is the best equipment for cutting samples. It is especially suitable for metallographic laboratory of factories, colleges and universities, scientific research institutions, and is an ideal choice for metallographic sample cutting.

2.the main function and characteristics

1, the shaft sleeve, and the main parts of the work table are made of corrosion-resistant materials, long life.

2, the workbench and the motor fixing frame are fixed and stable, and the surface is sandblasted, beautiful and durable

3, the workpiece is fixed with fast fixture, convenient and fast, safe and reliable (optional)

4, the whole mechanism rotates smoothly, low noise, long life

5, perspective using impact resistant transparent PC board, safe and reliable

6, the use of waterproof LED lights for lighting, easy to observe the whole process of cutting

7, with cooling device and water tank, so that the coolant can be recycled, saving and efficient

8. The maximum cutting diameter is 100mm

3.technical parameters

| Cutting method | Manual, y-feed |

| Slice size | Φ 300 x 2 x Φ 32 mm |

| Maximum cutting section | 100X100mm |

| Spindle speed | 2800r/min |

| Motor power | 2.2 kw |

| Overall power | 2.8 kw |

| Cutting jig | Threading jig |

| Lighting | Waterproof LED lighting |

| Water tank | Self-circulating tank |

| Input power supply | 380V, 50Hz, three-phase four-wire |

| Overall dimensions | 750X640X550mm |

| Weight | 100kg |

4. Configuration list

| Product accessories | Units | Quantity | Remarks |

| Auto cycle cooling tank | Taiwan | 1 | |

| Cutting sheet | a | 1 | |

| Wrench | a | 2 | |

| Water inlet pipe | The root | 1 | |

| Outlet hose | The root | 1 | |

| Technical documents | 1. Product manual 1 copy 2. Product certificate 1 copy | ||