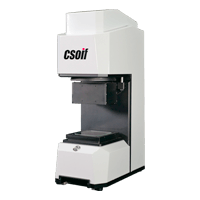

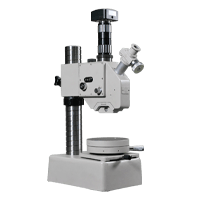

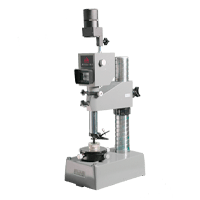

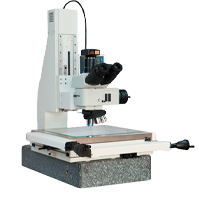

HRS-150 digital automatic Rockwell hardness tester has a novel appearance, a menu-based interface, the measuring device is controlled by a grating sensor and a computer, and the hardness display value is directly displayed on the LCD screen.

The function can automatically convert various hardness parameters to each other, identify the minimum thickness of the test piece and determine the ambient temperature of the test. Built-in printer to read relevant test results. Automated operation is achieved, eliminating human operation and reading errors.

1. Main functions and features:

1. Directly display the test hardness value through the large LCD screen.

2. The shell is cast by a special sand casting process, the structure is stable and not deformed, and it can work in a relatively harsh environment; the car paint is of high grade, with strong scratch resistance, and it is still bright as new after many years of use;

3. The machine provides parts replacement and maintenance upgrade services for life.

2. Main purpose and scope of application:

Cast and forged parts, sample testing and acceptance inspection, flat and cylindrical workpieces, steel, non-ferrous metals, automotive and aerospace, carbide, ceramics, stainless steel, laboratories and workshops.

3. Main technical parameters:

| parameter name | parameter data |

| Initial test force (N) | 10kgf(98.07N) Allowable error±2.0% |

| Total test force (N) | 60kgf(588N) 100kgf(980N) 150kgf(1471N) |

| Rock Ruler | HRA、HRB、HRC、HRD、HRE、HRF、HRG、HRH、HRK |

| Inspection standards | GB/T230.1 GB/T230.2 National Standard JJG112 Verification Regulations ASTM E18 |

| precision | 0.1HR |

| Dwell time (s) | 1-60 |

| Hardness reading method | LCD |

| Maximum allowable height of the test piece (mm) | 190 |

| Distance from the center of the indenter to the body (mm) | 165 |

| Durometer Dimensions (mm) | 520×240×720 |

| power supply | 220V/50HZ |

| Instrument weight (kg) | 70 |

| Hardness test range | HRA:20-88 HRB:20-100 HRC:20-70 HRD:40-77 HRE:70-94 HRF:60-100 HRG:30-94 HRH:80-100 HRK:40-100 HRL:100-120 HRM:85-110 HRR:114-125 |

4. Packing list:

| serial number | name (specification) | quantity |

| 1 | Diamond Rockwell Indenter | 1 |

| 2 | φ1.5875mm ball indenter | 1 |

| 3 | Daping test bench, Zhongping test bench, “V” type test bench | 3 in total |

| Standard Rockwell hardness block | ||

| 4 | HRB | 1 |

| 5 | HRC high, low | 2 pieces in total |

| 6 | Fuse 2A | 2 |

| 7 | power cable | 1 |

| 8 | RS-232 communication line | 1 |

| 9 | Weights A, B, C | 3 in total |

| 10 | Dust-proof plastic cover | 1 |

| 11 | Product certificate | 1 |

| 12 | Printer paper, printer instruction manual | 1 each |

| 13 | Instruction Manual | 1 |