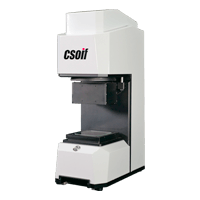

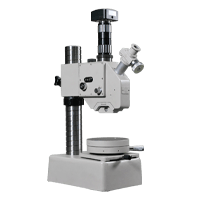

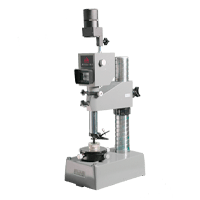

I. Purpose

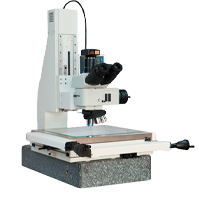

The digital micro hardness tester can meet the basic Vickers hardness test requirements, and the upgraded digital micro eyepiece can directly read the measurement length, so that the measured value can be obtained more quickly and accurately. The LCD large screen display is easy to observe, and the test conditions and test process are intuitive and clear. Steel, non-ferrous metals, metal foils, cemented carbides, metal sheets, microstructures; carburizing, nitriding and decarburizing layers, surface hardening layers, electroplating layers, coated glass, wafers, ceramic materials.

2. Features

The optical system designed by the senior optical engineer not only has clear images, but also can be used as a simple microscope, with adjustable brightness, comfortable vision, and long-term operation is not easy to fatigue; the large LCD screen of the industrial display screen can display the test method, test force, Measure indentation length, hardness value, converted hardness value, test force holding time, measurement times and can enter year, month, date, test results and data processing, etc. High grade, strong anti-scratch ability, and still bright as new after many years of use; our company has the ability to develop, design, produce and process by ourselves, and the machine provides parts replacement and maintenance and upgrade services for life; HVS-1000 model can measure the actual length and directly confirm it Hardness value.

Three, technical parameters

| parameter name | parameter data | |||||

| Micro hardness scale | HV0.01,HV0.025,HV0.05,HV0.1,HV0.2,HV0.3,HV0.5,HV1 | |||||

| show | Hold time (seconds), hardness value | |||||

| Test force (gf) | 10, 25, 50, 100, 200, 300, 500, 1000 | |||||

| Load control | Automatic (load/hold/unload) | |||||

| Test force holding time (s) | 5~60 | |||||

| Test force selection | External force selection knob, the test force is automatically displayed on the LCD screen | |||||

| Objective lens magnification | 10×, 40× | |||||

| Optical channel | Dual optical channels (eyepiece and CCD camera channel) | |||||

| Optical system | 1. Automatic digital encoder;2. Total magnification (μm): 100× (observation), 400× (measurement);

3. Measuring range (μm): 200; 4. Resolution (μm): 0.01 |

|||||

| Hardness measuring range | (5-3000)HV | |||||

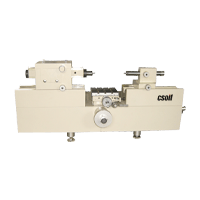

| XY test stand | Dimensions (mm): 100×100Stroke range (mm): 25×25

Minimum reading (mm): 0.01 |

|||||

| Maximum height of specimen (mm) | 110 | |||||

| Maximum width of specimen (mm) | 85 (distance from the center line of the indenter to the machine wall) | |||||

| data output | Reserved built-in micro-printer interface, (RS232 serial interface), optional installation | |||||

| voltage | AC220V/50HZ | |||||

| Weight (kg) | 35 | |||||

| Dimensions | 540×200×530 | |||||

Standard configuration

| Host | 1 set | Stand, weight, microscope accessory case | 1 |

| weights | 6pcs | weight bar | 1 |

| Cross table | 1 | sheet holder | 1 |

| Flat clamping table | 1 | filament holder | 1 |

| level | 1 | screws | 2 sets |

| leveling screw | 4pcs | External power cord | 1 root |

| 10X micrometer eyepieces | 1 piece | Micro Vickers hardness scale | 2 pieces (one each for HV1 and HV0.2) |

| fuse (1A) | 2 | Product Certificate | 1 serving |

| Product Instruction Manual | 1 serving | dust cover | 1pc |

Remark:

Optional side rocking lifting system makes the lifting system more stable and precise.

Optional built-in printer, one-key printing of measurement data, or upload to computer.

Optional hardness tester measurement software can eliminate human error, computer operation, improve efficiency and more accurate accuracy.