I. Purpose

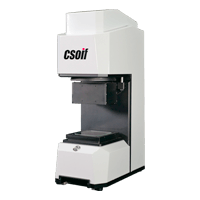

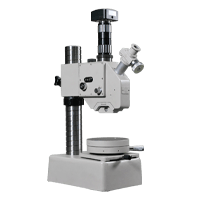

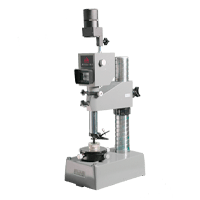

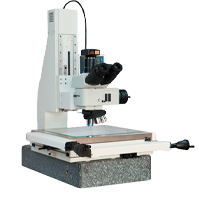

The digital automatic turret Vickers hardness tester can meet the basic testing requirements of Vickers hardness tester. The microscope eyepiece can directly read the measurement length, so that the measurement value can be obtained more quickly and accurately. The upgraded turret can automatically switch the eyepiece and the indenter to avoid manual error causing damage to the instrument, and also greatly improve the efficiency.

1. steel, non-ferrous metals, metal foils, cemented carbides, metal sheets, microstructures, carbonization;< /span>

2, carburizing, nitriding and decarburization layer, surface hardening layer, electroplating layer, coating, heat treatment ;

3. glass, wafer, ceramic material;

II. Features

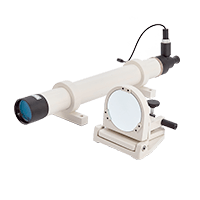

1. The optical system designed by the senior optical engineer not only has clear images, but also can be used as a simple microscope with high brightness. Adjustable, visual comfort, long-term operation is not easy to fatigue;

2. The large LCD screen of the industrial display screen can display the test method, test force, and measure the indentation length , hardness value, converted hardness, test force holding time, measurement times and can enter year, month, date, test results and data processing, etc.;

3. The cast aluminum shell is formed at one time, the structure is stable and not deformed, the car paint grade is high, and the scratch resistance Strong, still bright as new after many years of use;

4, Our company has the ability to develop and design, produce and process by ourselves, and our machines provide parts replacement and maintenance for life Upgrade service;

5. HVS-10Z model can measure the actual length and directly confirm the hardness value;

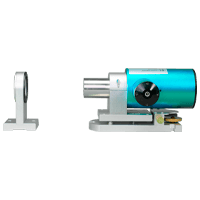

6. HVS-10Z model can realize: the position switching of observation-test-measurement is completed by automatic turret ;

7. Large LCD display is convenient for observation, test conditions and test process are intuitive and clear;

8. Optional built-in printer; test results and test data can be printed directly;

III. Technical parameters

| Model | HVS-5Z | HVS-10Z | HVS-30Z | HVS-50Z | ||||||||

| Vickers hardness scale | HV0.3,HV0.5,HV1.0,HV2.0,HV3.0,HV5.0 span> | HV0.3,HV0.5,HV1.0,HV3.0,HV5.0,HV10.0 span> | HV1,HV3,HV5,HV10,HV20,HV30 | HV1 ,HV5,HV10,HV20,HV30, HV50 | ||||||||

| display | 5-digit hardness value, 4-digit diagonal length (D1, D2), hold time, test times, mean, standard deviation, return | |||||||||||

| Test force (Kgf) | 0.3, 0.5, 1.0, 2.0, 3.0, 5.0 | 0.3, 0.5, 1.0, 3.0, 5.0, 10.0 | 1.0Kgf(9.8N), 3.0Kgf(29.4N),

5.0Kgf(49.0N), < /span> 10Kgf(98.0N), 20Kgf(196N), 30Kgf(294N) |

1.0Kgf(9.8N), 5.0Kgf(49.0N),

10Kgf(98.0N), 20Kgf(196N), 30Kgf(294N), 50Kgf(490N) |

||||||||

| Load Control | Automatic (load/hold/unload) | |||||||||||

| Test force holding time(s) | 1~99 | |||||||||||

| Light channel | Dual optical channels (eyepiece and CCD camera channel) | |||||||||||

| optics | Objectives: 10×, 20× (optional 40X)Eyepiece magnification: 10×

Total magnification (μm): 100×, 200× Measuring range(μm):400 Resolution(μm):0.125 |

Objectives: 10×, 20×Eyepiece magnification: 10×

Total magnification (μm): 100×, 200× Measuring range(μm):400 Resolution(μm):0.125 |

Objectives: 10×, 20× (40X optional)Eyepiece magnification: 10× (optional 15X)

Total magnification (μm): 100×, 200× Measuring range(μm):400 Resolution(μm):0.125 |

Objectives: 10×, 20×Eyepiece magnification: 10× (can be changed to 15X)

Total magnification (μm): 100×, 200× (can be changed to 150X, 300X) Measuring range(μm):400 Resolution(μm):0.125 |

||||||||

| Hardness measurement range | (5-3000)HV | |||||||||||

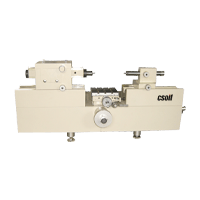

| XY stage | Size(mm):100×100Stroke range(mm):25×25

Min reading (mm): 0.01 |

|||||||||||

| Maximum specimen height (mm) | 165 | |||||||||||

| Maximum width of specimen (mm) | 130(distance from indenter center line to machine wall) | |||||||||||

| Data output | Reserved built-in micro-printer interface, (RS232 serial interface) optional installation | |||||||||||

| Supply Voltage | AC220V/50HZ | |||||||||||

| Dimension (mm | 585×200×630 | |||||||||||

| Weight(kg) | 42 | |||||||||||

Attachments

HVS-5Z

| Host | 1 set |

| weights | 3 |

| Cross measurement platform | 1 piece |

| Flat clamping table | 1 |

| leveling screw | 4pcs |

| Power cord | 1 root |

| 10X digital micrometer eyepiece | 1 piece |

| Vickers hardness block | 2 blocks |

| Spare fuse 2A | 2pcs |

| Product Certificate | 1 serving |

| Product Instruction Manual | 1 serving |

HVS-10Z

| Host | 1 set |

| weights | 3 |

| Cross measurement platform | 1 piece |

| Flat clamping table | 1 |

| leveling screw | 4pcs |

| Power cord | 1 root |

| 10X digital micrometer eyepiece | 1 piece |

| Vickers hardness block | 2 blocks |

| Spare fuse 2A | 2pcs |

| Product Certificate | 1 serving |

| Product Instruction Manual | 1 serving |

HVS-30Z

| Host | 1 set |

| weights | 3 |

| large and medium “V” type test stand | 1 of each |

| leveling screw | 4pcs |

| Power cord | 1 root |

| 10X digital micrometer eyepiece | 1 piece |

| Vickers hardness block | 2 blocks |

| Spare fuse 2A | 2pcs |

| Product Certificate | 1 serving |

| Product Instruction Manual | 1 serving |

HVS-50Z

| Host | 1 set |

| weights | 3 |

| large and medium “V” type test stand | 1 of each |

| leveling screw | 4pcs |

| Power cord | 1 root |

| 10X digital micrometer eyepiece | 1 piece |

| Vickers hardness block | 2 blocks |

| Spare fuse 2A | 2pcs |

| Product Certificate | 1 serving |

| Product Instruction Manual | 1 serving |

Note:Optional hardness tester measurement software to eliminate human error, computer operation, improve efficiency and more accurate accuracy.