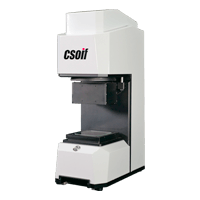

Product introduction

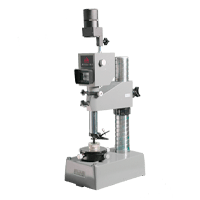

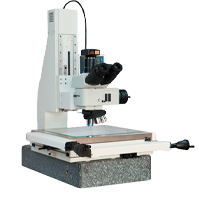

JB-4C precision roughness tester is a high-precision stylus-type surface roughness measuring instrument. The surface roughness is tested, and the shape, contour and other parameters of the surface roughness can be measured, and the TP steps of the workpiece can also be measured. The instrument is easy to use, with high measurement accuracy and stable repeatability.

The instrument is equipped with a computer and special measurement software, and uses an advanced noise-free mechanical positioning device, which can select different positions of the measured part, set various measurement lengths for automatic measurement, and the sampling data in the evaluation section reaches 3000 points. All measurement data and curves can be displayed on the screen or printed out, so it is widely used in various industries such as automobile supporting industry, machinery, mold processing, scientific research units, colleges and universities.

The instrument meets the requirements of national standards GB/T3505-2000, GB/T6062-2001, GB/T10610-1998, and international standards ISO5436 and ISO11562.

Technical Specifications

Instrument gross weight

| model | JB-4C |

| Test parameters | Ra,Rz,Rt,RS,RSm,Rp,Rv,Rmax,Rq,D,Pt, Lr, Ln, RSk, RΔq, Δa, λq, λa, R3t, Rt1, Rt2, Rt3, RT4, rt5, etc., Rmr(Tp) curve |

| Vertical magnification of outline graphics | 10,20,50,100,200,500,1000,2000,5000,10000,20000,50000,100000,200000,500000 or automatically |

| Roughness measurement range | Ra 0.01 – 50 μm |

| Sampling length | L: 0.08 ,0.25, 0.8,2.5 mm |

| Assessment length | Ln: 1L, 2L, 3L, 4L, 5L optional |

| Instrument evaluation sampling | 4000 points |

| Resolution | 0.001 μm |

| Indication error | ±5 % |

| Measurement repeatability | ± 3 % |

| Measure the maximum height of the workpiece | 300mm |

| The sensor can measure | Surface roughness of various parts such as plane, inclined surface, inner hole surface, outer cylindrical surface, deep groove surface, arc surface, spherical surface, etc. |

| Natural diamond stylus | Standard type, height <8mm

Small hole type Stylus radius: 2um, measuring force: 4 mN |

| Glide speed of drive case | 2mm/s |

| Lifting form of drive box | Automatic lift |

| Moving speed | 0.5 mm/sec |

| Linear area | Vertical 640 um |

| Step and Pt measurement range | 100 um |

| resolution | 0.1 um |

| Axial measuring range | 60 mm |

| Outline graphics | direct contour, filtered contour |

| X, Y magnification ratio of contour graphics | automatically selected |

| filter | ISO 2CR filter |

| Small hole measuring range | ≥ Ø5 mm |

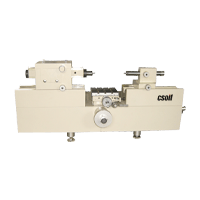

| X-Y table | Rotation angle ±10°

X-Y movement range 15 mm |

| Bearing inner and outer ring size | The maximum outer diameter of the inner ring is 280mm

The minimum diameter of the outer ring is 12mm Thickness≤160mm |

| Paper Specifications | A4 paper |

| operating system | WinXP |

| Instrument power | 220 VAC±10%, 50Hz |

| Marble table size | 640×400×100mm |

| 150 kg |

Instrument standard configuration list

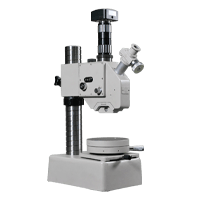

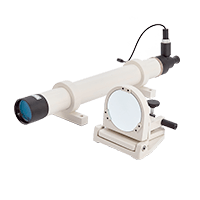

1. Pillar and marble base 1 piece

2. Controller 1 piece

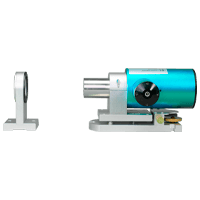

3. 1 drive unit

4. Sensor 1 piece

5. 1 set of X-Y workbench

6. 1 V-shaped table

7. A/D conversion card 1 piece

8. 1 signal line

9. 1 signal control line

10. 1 standard contact pin

11. 1 small hole type contact pin

12. 1 roughness sample

13. 1 set of measurement software and installation disk

14. 1 set of Lenovo commercial computer and HP inkjet printer