I. Purpose

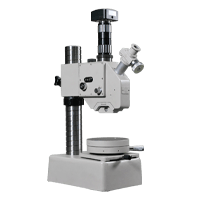

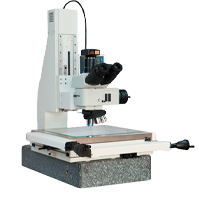

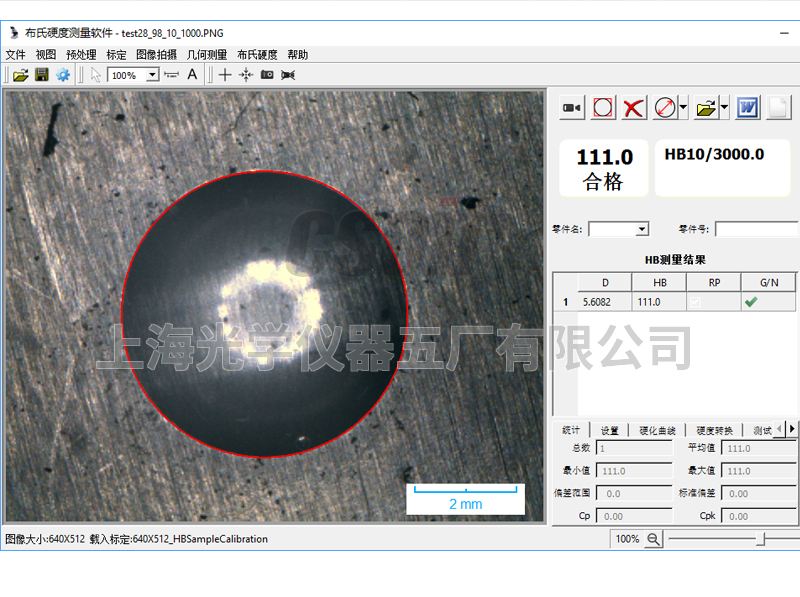

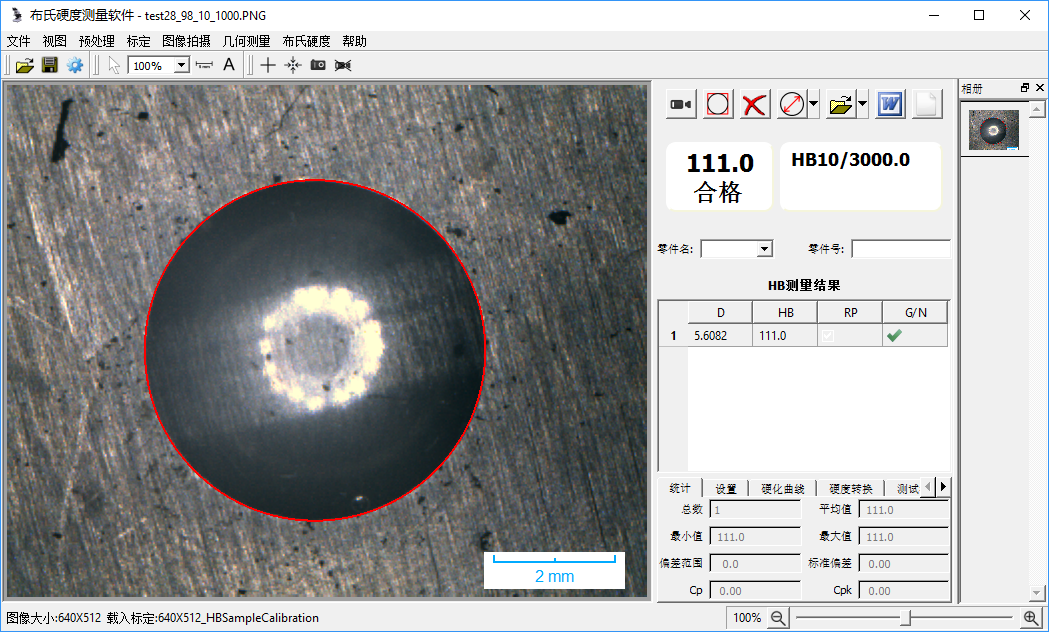

1. Automatic measurement: Automatically or manually capture the indentation and measure the indentation diameter and calculate the corresponding Brinell hardness value;

2. HB2 automatic measurement (German industrial standard DIN1605): automatically or manually measure the indentation diameter of the standard test block and the test piece, and automatically calculate the HB value of the test piece by looking up the table and interpolating;

3. Hardness value conversion, effective verification: The system can convert the measured Brinell hardness value HB into other hardness values such as HV, HR, etc.;

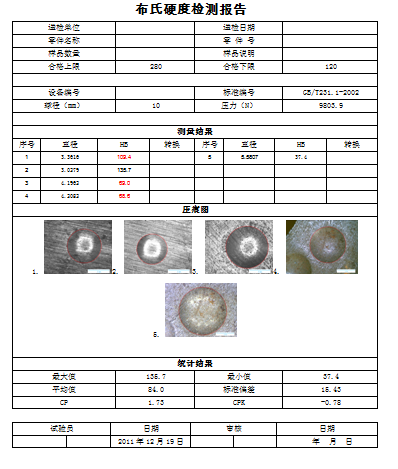

4. Data statistics: The system automatically calculates and saves the average, variance and other statistical values of the measured hardness;

5. Over-standard alarm: Automatically mark abnormal values, when the hardness exceeds the specified value, it will automatically alarm;

6. Test report: Automatically generate WORD or EXCEL format report, report template can be customized;

7. Data Storage: Measurement data including indentation images can be stored in available documents;

Other features: Contains all the features of a microscope image processing and measurement system, including Image capture, calibration, image processing, geometric dimension measurement, document annotation, album management, and fixed-size printingetc; for Brinell hardness indentation measurement.

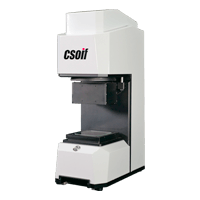

2. Features

Easy to use: click the interface button or press the camera button or press the run key to Automatically complete all the work; if you need to manually measure or modify the results, just drag the mouse;

High noise immunity: Advanced and reliable image recognition technology can handle the pressure on the surface of complex samples Trace recognition, two automatic measurement modes to handle extreme cases;

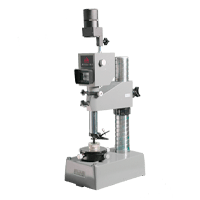

Three, technical parameters

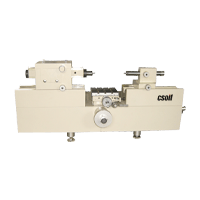

| Parameter name | Parameter range | ||||||

| Applicable test force range | 1, 5, 10, 15.625, 30, 31.25, 62.5, 100, 125, 187.5, 250, 500, 750, 1000, 1500, 3000kgf | ||||||

| Applicable indenter diameter | 1mm, 2.5mm,5mm,10mm | ||||||

| Applicable indentation measurement range | 0.24-6.0mm, the recommended indentation diameter is within 0.4mm – 6.0mm Better | ||||||

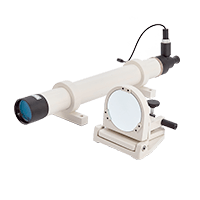

| Four fixed magnifications can be adjusted to ensure measurement accuracy, respectively applicable to the indentation size range | 0.5-1.6mm (70X)

1-2.0mm (55X) 2-4.0mm (30X) 3-6.0mm (20X)) |

||||||

| Indentation measurement accuracy | ±0.5% | ||||||

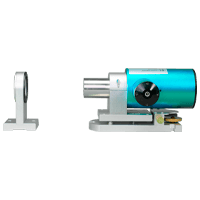

| Camera | 2 million pixels 1/3 inch CMOS USB camera, aluminum alloy metal shell with 304 stainless steel Magnetic base with push button switch to directly start software and trigger measurements | ||||||

| max resolution | 1600×1200, power consumption: 75mW | ||||||

| SNR | 68db | ||||||

| USB cable | 1.5m and 3m each | ||||||

| Power | Computer USB powered | ||||||

| Computer system requirements: | Windows XP, Windows 7, Windows 8, Windows 10 32-bit or 64-bit Desktop or notebook, PC computer

Two USB ports are required, and Microsoft Office (WORD and EXCEL) 2007 version is required or above for generating reports |

||||||

| Software configuration | Automatic measurement of indentation and calculation of Brinell hardness according to ASTM E10 standards | ||||||

| According to German Industrial Standard DIN1605, automatic measurement of test sample indentation and standard block indentation and calculation Hammer Brinell Hardness HB2 | |||||||