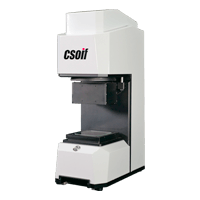

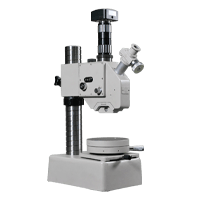

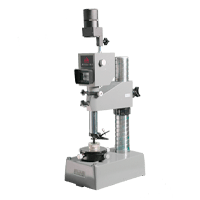

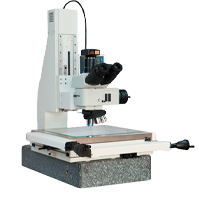

The metallographic image analysis system (software) integrates today’s advanced image analysis technology, which is the perfect combination of metallographic microscope and intelligent analysis technology. The measurement and rating results are fast and accurate, and conform to the national standard and the American ASTM standard. The system interface is all finished in Chinese, which is concise, clear and easy to operate. After simple training or referring to the instruction manual, it can be operated freely.

The system includes the following functions:

Image editing software: more than ten functions such as image acquisition and image storage;

Image software: more than ten functions such as image enhancement and image overlay;

Image measurement software: dozens of measurement functions such as perimeter, area, and percentage content;

Output mode: data table output, histogram output, image print output.

Dedicated metallographic software packages:

Grain size measurement and rating (grain boundary extraction, grain boundary reconstruction, single phase, dual phase, grain size measurement, rating);

Measurement and rating of non-metallic inclusions (including sulfides, oxides, silicates, etc.);

Pearlite and ferrite content measurement and rating; ductile iron graphite nodularity measurement and rating;

Decarburization layer, carburized layer measurement, surface coating thickness measurement;

Phase-area measurement of ferritic and austenitic stainless steels;

Analysis of primary silicon and eutectic silicon of high silicon aluminum alloy;

Nearly 200 professional projects such as titanium alloy material analysis, meet the requirements of metallographic analysis and inspection of most units.