I. Purpose

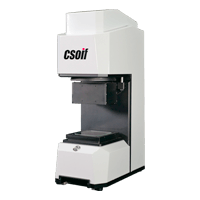

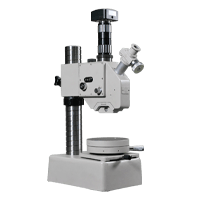

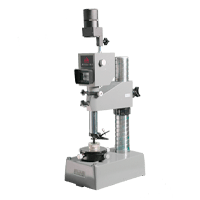

SHL-160 Portable Leeb Hardness Tester is a new generation flagship model developed by our company. It adopts ultra-low power consumption design concept, high-performance rechargeable battery, intelligent charging management and USB plug-and-play communication interface, and comes with embedded thermal printer, which supports on-site instant printing, meets diverse measurement requirements, and has ultra-high Brightness display LCD screen can better meet the complex measurement environment and meet the needs of most users.

2. Features

1. Full Chinese display, menu operation

2. Mini USB communication interface

3. It can be equipped with 7 different impact devices, no need to recalibrate when replacing, and can automatically identify the type of impact device

4. Support measurement of various hardness scales and three strength values

5. It can store 450 groups, single measurement value, average value, measurement date, impact direction, number of times, material, hardness scale and other information

6. The upper and lower limits of the hardness value can be set in advance. If the limit is exceeded, it will automatically alarm, which is convenient for users to test in batches.

7. Indication software calibration function

8. Built-in high-performance lithium battery and charging control circuit, with long working and standby time

9. Can be equipped with computer software to support functions such as data query, storage, statistics and histogram display

Three, technical parameters

| parameter name | parameter data | ||||||

| hardness scale | Richter (HL), Brinell (HB), Rockwell A (HRA), Rockwell B (HRB), Rockwell C (HRC), Vickers (HV) and Shore (HS) | ||||||

| Measuring range | HLD (170~960), HRA (59~85), HRB (13~100), HRC (18~68), HB (19~655), HV (80~976), HS (32~100) | ||||||

| Measurement direction | 360°(vertically down, diagonally down, horizontal, diagonally up, vertical up) | ||||||

| Measuring material | Steel and cast steel, alloy tool steel, stainless steel, grey cast iron, ductile iron, cast aluminium alloy, copper-zinc alloy (brass), copper-tin alloy (bronze), pure copper and wrought steel | ||||||

| show | LCD,128×64 Graphic dot matrix LCD | ||||||

| print function | Thermal print head, quiet operation, ready to print measurement results | ||||||

| printer paper | Width 57.5±0.5mm, diameter 30mm | ||||||

| data storage | 373~2688 groups (the number of impacts is 32~1) | ||||||

| Communication interface standard | USB2.0 | ||||||

| power plug | 9VDC, 220VAC | ||||||

| charging time | 4 to 5 hours | ||||||

| Battery | 7.4V, lithium battery (1500mAh) | ||||||

| ambient temperature | 0~40℃ | ||||||

| storage temperature | -25~70℃ | ||||||

| continuous working time | about 300 hours | ||||||

Indication error and indication repeatability

| serial number | Shock device type | Standard Leeb hardness value | Indication error | Indication repeatability |

| 1 | D | 760±30HLD

530±40HLD |

±5 HLD

±8 HLD |

5 HLD

8 HLD |

| 2 | DC | 760±30HLDC

530±40HLDC |

±5 HLDC

±8 HLDC |

5 HLD

8 HLD |

| 3 | DL | 878±30HLDL

736±40HLDL |

±10 HLDL | 10 HLDL |

| 4 | D+15 | 766±30HLD+15

544±40HLD+15 |

±10 HLD+12 | 10 HLD+12 |

| 5 | G | 590±40HLG

500±40HLG |

±10 HLG | 10 HLG |

| 6 | E | 725±30HLE

508±40HLE |

±10 HLE | 10 HLE |

| 7 | C | 822±30HLC

590±40HLC |

±10 HLC | 10 HLC |

Specimen configuration:

Instrument host 1Tai

DType Impact Device 1only

Small support ring 1only

Nylon brush (I) 1only

High-value Richter scale 1< span style=”font-family:Arial”>Block

Charger 1only

Communication cable 1bar

Options:

Data processing software (application on computer) span>

Various shaped impact devices and support rings span>

High, medium and low value Leeb hardness blocks