I. Purpose

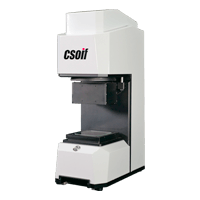

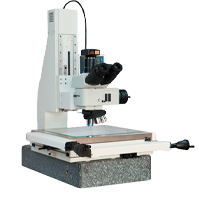

The surface roughness measuring instrument is suitable for laboratories and production sites. It can measure the surface roughness of various machined parts, including flat surfaces, inclined surfaces, outer cylindrical surfaces, curved surfaces, small holes, grooves and axles, etc., according to the selected measurement The corresponding parameters are calculated according to the conditions, and the measurement results and contour graphics are clearly displayed on the liquid crystal display.

2. Features

1. Mechatronics design, small size, light weight, easy to use;

2. High-precision inductive sensor;

3. Using DSP chip for control and data processing, fast speed and low power consumption;

4. GAUSS filter;

5. 128×64 dot matrix OLED LCD screen

6. Built-in lithium-ion rechargeable battery and charging control circuit, high capacity, no memory effect, continuous working time is more than 20 hours;

7. With automatic shutdown, memory and various information;

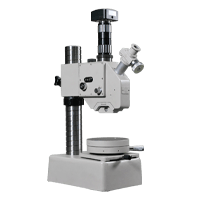

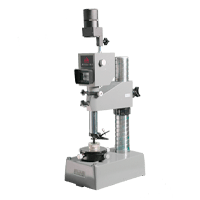

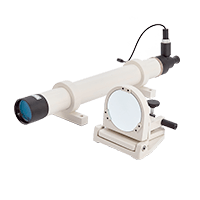

8. Optional accessories such as curved surface sensor, small hole sensor, measuring platform, extension rod, etc.

9. Compatible with ISO, DIN, ANSI, JIS national standards;

10. The system language can be switched between Chinese and English, and the default Chinese system when booting

11. The unit can be changed in order: industrial system→imperial system; the default value is industrial system.

Three, technical parameters

| name | Content | |||

| Measurement

scope |

Z axis (vertical) | 200μm | ||

| X-axis (horizontal) | 15mm | |||

| Resolution | Z axis(vertical) | 0.01μm/±20μm | ||

| 0.02μm/±40μm | ||||

| 0.04μm/±80μm | ||||

| Measurement

project |

parameter | Ra, Rq, Rsm, Rsk, Rz, Rt, Rp, Rv, Rc, Rco | ||

| standard | ISO,ANSI,DIN,JIS | |||

| graphics | Support rate curve, roughness profile, direct profile | |||

| filter | GAUSS filter | |||

| Sampling length (lr) | 0.25,0.8,2.5mm | |||

| Assessment length (ln) | Ln= lr×n n=1~5 | |||

| sensor | Measurement principle | Displacement Differential Inductive | ||

| stylus | Natural diamond, 90 cone angle, 5μm tip radius | |||

| Force measurement | <4mN | |||

| guide | Carbide, radius 45mm in sliding direction | |||

| taxi speed | lr=0.25, Vt=0.135mm/s | |||

| lr=0.8, Vt=0.5mm/s | ||||

| lr=2.5, Vt=1mm/s | ||||

| Back Vt=1mm/s | ||||

| Indication error | Not more than ±10% | |||

| Indication variability | not more than 6% | |||

| power supply | Built-in lithium-ion rechargeable battery, charge with DC5V, 800mA charger | |||

| Dimensions | 158×63.5x46mm | |||

| weight | About 300g | |||

| working environment | Temperature: – 20℃ ~ 40℃ Humidity: < 90% RH | |||

| storage and transportation environment | Temperature: – 40℃ ~ 60℃ Humidity: < 90% RH | |||

Measurement rangeRange:

| parameter | Display range |

| Ra,Rq | 0.005μm ~ 16μm |

| Rz,R3z,Ry,Rt,Rp,Rm | 0.02μm ~ 160μm |

Standard configuration:

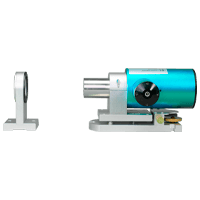

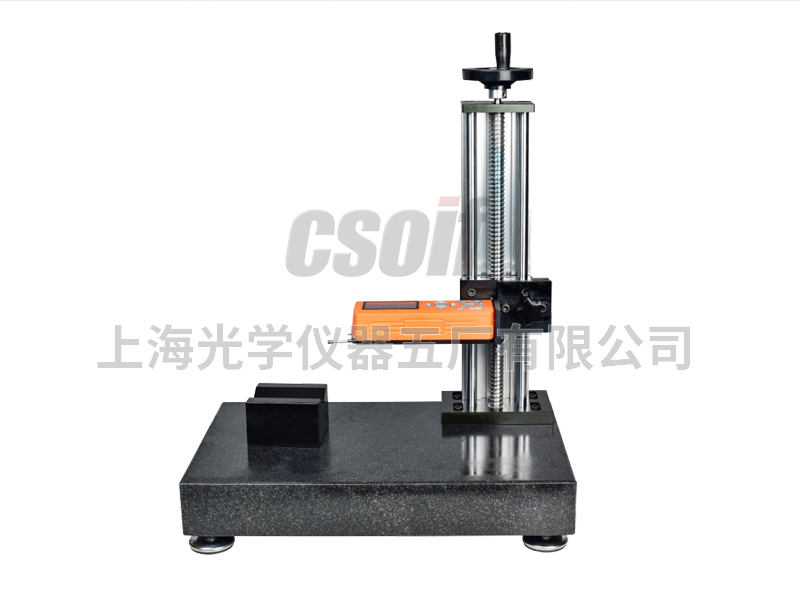

| SHT-180 Roughness Tester Host | 1 set | Standard sensor | 1 |

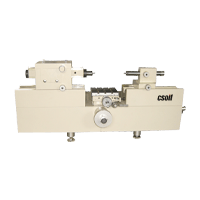

| Multi-reticle standard sample | 1 block | Adjustable stand | 1 |

| Power Adapter | 1 set | manual | 1 |

| certificate | 1 | Warranty Card | 1 |