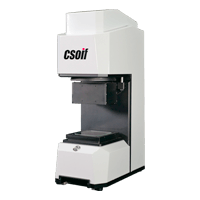

1、 Purpose

Metallographic specimen inlay is a very important step in the preparation process of metallographic specimens, especially suitable for some small and difficult to hold samples or irregularly shaped samples. After inlaying, the overall dimensions are fixed and unified, making it easy to hold or perform subsequent fully automatic polishing (it can be used together with our company’s fully automatic polishing machine for better results). Especially suitable for specimens that require edge protection or automatic grinding and polishing, the embedding of specimens is an essential process, especially suitable for metallographic laboratories in factories, universities, and research institutions.

2、 Characteristics

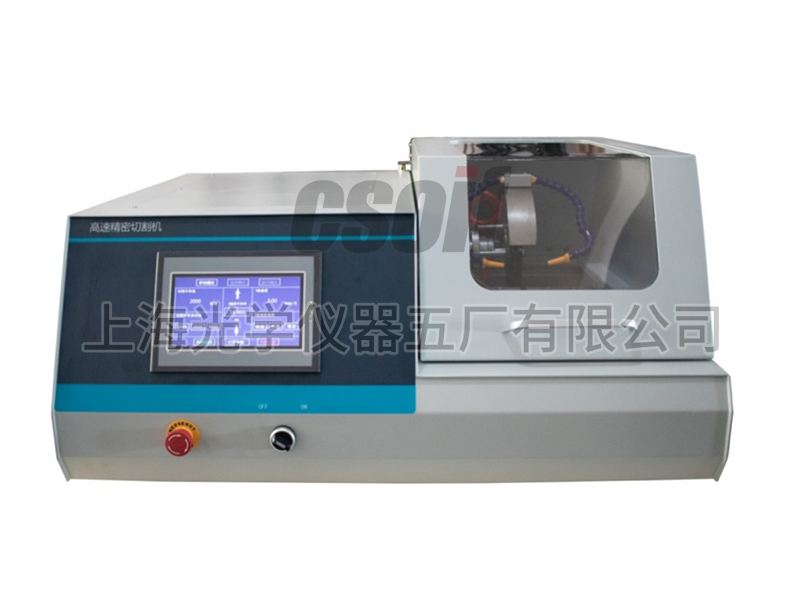

1. The shell adopts high-end ABS integrated molding, with a novel appearance and high-end atmosphere.

2. Touch screen display control, clear and intuitive interface, easy to operate.

3. Adopting precision mechanical transmission for pressurization, durable and durable.

4. The entire process is fully automatic closed-loop control, and all embedding processes can be completed automatically with just one click.

5. Equipped with a cooling system, it cools faster and has higher embedding efficiency. The cooling mode can be selected as time cooling mode, with a set cooling time that automatically stops when the temperature is reached. The temperature cooling mode can also be selected, with a set cooling temperature that automatically stops when the temperature is reached.

6. Multiple mold specifications are available, and special molds can be customized according to customer needs.

7. It can be operated manually or automatically, and can be operated DIY according to customer needs, making it more flexible and convenient to use.

8. It can store over 100 sets of inlay process formulas, making it easy to quickly call and achieve serial production.

9. We can meet various customized needs according to customer needs and provide comprehensive one-stop service.

10. Two samples can be embedded simultaneously, instantly doubling the embedding efficiency.

11. The program has built-in intelligent algorithms, which can select time mode and intelligent mode (especially suitable for first-time users).

3、 Technical parameters

| name | parameter | ||||

| Mold specifications | Standard configuration φ 30 (optional: φ 22, φ 45), special customizable | ||||

| Effective depth of mold | 70mm | ||||

| Power | 2KW | ||||

| Afterburner method | Electromechanical pressurization | ||||

| Temperature setting range | 0-200 degrees Celsius | ||||

| Pressure maintaining setting range | 0-99 minutes | ||||

| Cooling setting range | 0-99 minutes | ||||

| Embedding time | Within 6 minutes (from heating to 155 degrees to cooling to within 40 degrees),

In the case of black inlay material and inlay thickness within 20mm) |

||||

| Suitable for inlaying materials | thermosetting | ||||

| power supply | Voltage: 220V; Frequency: 50HZ | ||||

| total power | 2.2KW | ||||

| Overall dimensions | 460X580X550 | ||||

| weight | 60KG | ||||

4、 Configuration List

| Accessories | unit | number | notes | |

| Φ30 mold components | 1 | pieces | Installed on device | |

| Inlay material (black) | 500 | can | ||

| Feeding spoon | 1 | pieces | ||

| funnel | 1 | pieces | ||

| brush | 1 | pieces | ||

| water inlet | 1 | piece | 6 sub interfaces | |

| Outlet pipe | 1 | piece | ||

| Technical documents | 1 product manual | 1 product qualification certificate | ||