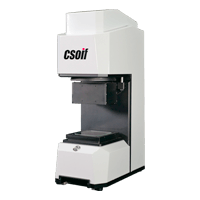

1、 Purpose

ZMP-1A is a single disc fully automatic grinding and polishing machine that integrates pre grinding, grinding, and polishing. It adopts microcontroller technology and is controlled through a touch screen. The grinding disc is driven by a DC brushless motor, and the V-belt is used for transmission. The grinding head is driven by a stepper motor, and the synchronous belt is used for transmission. It has the characteristics of stable rotation, low noise, long service life, safety and reliability; You can adjust the rotational speed of the grinding head and grinding chuck according to user needs, set the pressure and sample preparation time to meet different needs; Equipped with a lighting system for easy access and placement of samples; Equipped with a cooling device, it can cool the sample during grinding to prevent damage to the metallographic structure due to overheating of the sample. It is an ideal choice for metallographic sample preparation equipment in factories, research institutions, and universities.

2、 Characteristics

1. The base is made of aluminum alloy material and cast into one piece, with light weight and good shock absorption ability, and corrosion resistance.

2. The shell is formed using ABS suction molding, with a novel appearance and corrosion resistance.

3. The faucet adopts a full copper chrome plating process, which has good corrosion resistance.

4. Adopting touch screen control and display, easy to operate, clear and intuitive.

5. One click automatic start function. After the sample is placed in the clamping plate, click start, the pressure head will automatically press down, the grinding head and grinding plate will automatically run, the faucet will automatically discharge water, and after the grinding and polishing is completed, the faucet will automatically close.

6. It has the function of timing, speed, and pressure control.

7. Built in nozzle sump for automatic cleaning.

8. Support infinite speed regulation or four speed regulation mode, making speed regulation more convenient.

9. The grinding head adopts electromagnetic clutch automatic locking, which is convenient and fast. (Optional).

9. The grinding head adopts electromagnetic clutch automatic locking, which is convenient and fast. (Optional).

11. It can store more than 10 sets of grinding and polishing process parameters for quick retrieval.

12. Magnetic disc design, supporting quick disc replacement, making sandpaper and polishing fabric replacement more efficient and efficient.

13. The sample holder automatically relaxes and tightens, combined with the inner lighting system, making it easy to retrieve and place the sample.

14. Equipped with a fast sample clamping disc, it can be replaced with clamping discs of different diameters at any time.

15. The entire machine adopts a DC brushless and stepper motor, which rotates smoothly, has low noise, and long service life.

16. The emergency stop button can conveniently and quickly stop the operation, making it safer.

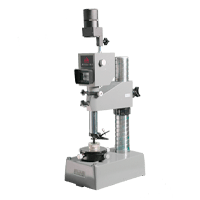

3、 Technical parameters

| Model | ZMP-1A | |||

| Number of grinding discs | 1 | |||

| Grinding disc diameter | 254mm | |||

| Grinding disc speed | Stepless speed regulation 100-1000r/minFour speed regulation300 500 800 1000r/min | |||

| Grinding disc rotation direction | Grinding disc rotation direction | |||

| Grinding disc motor power | 1.1KW | |||

| Grinding head rotation direction | clockwise | |||

| Grinding head speed | 0—120r/min | |||

| Grinding head motor | stepping motor 200W | |||

| Grinding head locking method | Manual (optional automatic) | |||

| Timing adjustable time | 0-99min | |||

| Pressure regulation method | Mechanical voltage regulation | |||

| Way of Pressure | Single point pneumatic pressurization | |||

| Pressurization pressure | 0-0.5Mpa(in common use0.2-0.3Mpa) | |||

| Sample clamping quantity | 6 | |||

| Thickness of specimen | 8-22mm(Customizable) | |||

| Sample clamping specifications | Standard configuration Ф 30(Ф 22 Ф 30 Ф 45

Any specification is optional, special specifications can be customized) |

|||

| power supply | 220V 50Hz | |||

| total power | 1.8kw | |||

| Overall dimensions | 475*660*710mm | |||

| weight | 80kg | |||

4、 Configuration List

| name | number | unit | notes | |

| millstoneΦ254 | 1 | pieces | Installed on device | |

| Magnetic disk | 1 | pieces | Installed on device | |

| water deflector | 1 | pieces | Installed on device | |

| Anti stick disc | 2 | pieces | Φ250mm | |

| 400 mesh adhesive sandpaper | 4 | fix | Φ250mm | |

| 800 mesh adhesive sandpaper | 4 | fix | Φ250mm | |

| 1200 mesh adhesive sandpaper | 4 | fix | Φ250mm | |

| Polishing cloth with adhesive | 4 | fix | Φ250mm | |

| water inlet | 1 | piece | 6 sub interfaces | |

| Outlet pipe | 1 | piece | Φ32 | |

| Technical documents | 1 product manual | 1 product qualification certificate | ||