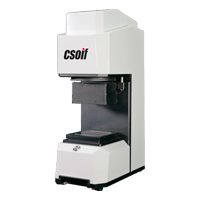

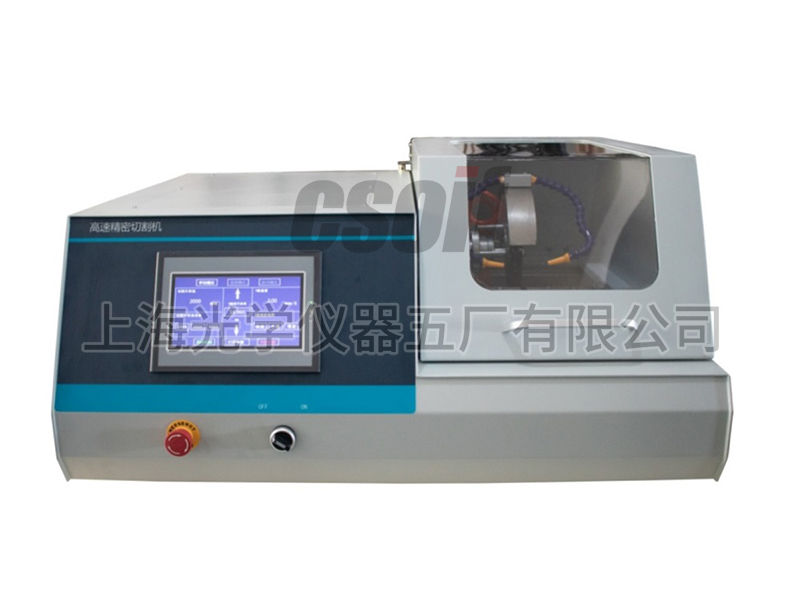

1.Product Overview

Metallographic specimen inlay is a very important link in the process of metallographic specimen preparation, especially for some small samples that are not easy to handle or samples with irregular shape. After inlay, its outline size is fixed and unified, easy to handle or carry out follow-up automatic grinding and polishing (can be used together with the company's automatic grinding and polishing machine, the effect is better). Especially suitable for the sample that needs to protect the edge or the sample that needs to be automatically grinding and polishing, the inlaying of the sample is an essential process, especially suitable for the metallographic laboratory of factories, colleges and universities and scientific research units, is a good choice for metallographic sample inlaying.

2.Main functions and characteristics

1. The shell adopts high-end ABS integrated molding, novel appearance, high-end atmosphere and high grade.

2. Touch screen display control, clear and intuitive interface, easy to operate.

3. Adopt precision mechanical transmission pressure, durable.

4. The whole process is fully automatic closed-loop control, only one key to automatically complete all the Mosaic process.

5. With cooling system, cooling faster, Mosaic efficiency is higher, cooling mode can choose time cooling mode, set cooling time, then automatically stop, you can also choose temperature cooling mode, set cooling temperature, reach the temperature automatically stop.

6. A variety of mold specifications are optional, and special molds can be customized according to customer needs.

7. Manual operation can be automatic operation, according to customer needs can be any DIY operation, the use of more flexible and convenient.

8. Can store more than 100 groups of Mosaic process formula, easy to call quickly, to achieve serialized production.

9. According to customer needs to meet customer customized needs, a full range of one-stop service.

10. Optional chiller, to achieve refrigeration cycle to solve the faucet shackles. (Optional)

11. The program built-in intelligent algorithm, can choose the time mode and intelligent mode (especially for the first time users).

3. Technical parameters

name | Parameters |

Mold specifications | Standard φ30 (optional: φ22, φ45), special can be customized |

Effective depth of mold | 30mm |

Heating power | 1KW |

Afterpower mode | Electro-mechanical compression |

Temperature setting range | 0-190C |

Pressure holding setting range | 0-99 minutes |

Cooling setting range | 0-99 minutes |

Mosaic time | Within 6 minutes (from heating to 155 ° C to cooling to 40 ° C, in the case of black inlay and inlay thickness within 15mm) |

Suitable inlay material | thermosetting |

Power supply | Voltage: 220V Frequency: 50HZ |

Total Power | 1.2 KW |

Overall dimensions | 460X580X550 |

Weight | 60KG |

4. Configuration list

Product accessories | Units | Quantity | remark |

Φ30 mold assembly | 1 | a | Already installed on the device |

Inlay (black) | 500 | g | |

Topping spoon | 1 | a | |

Funnel | 1 | a | |

Bristle brush | 1 | a | |

Water inlet pipe | 1 | The root | 6 point interface |

Outlet hose | 1 | The root | |

Technical documents | 1 copy of product specification 1 copy of product certificate | ||