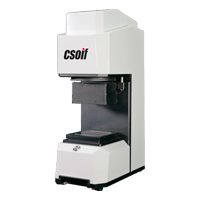

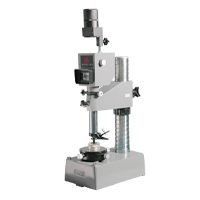

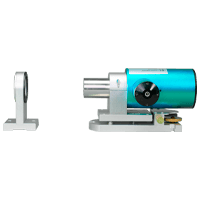

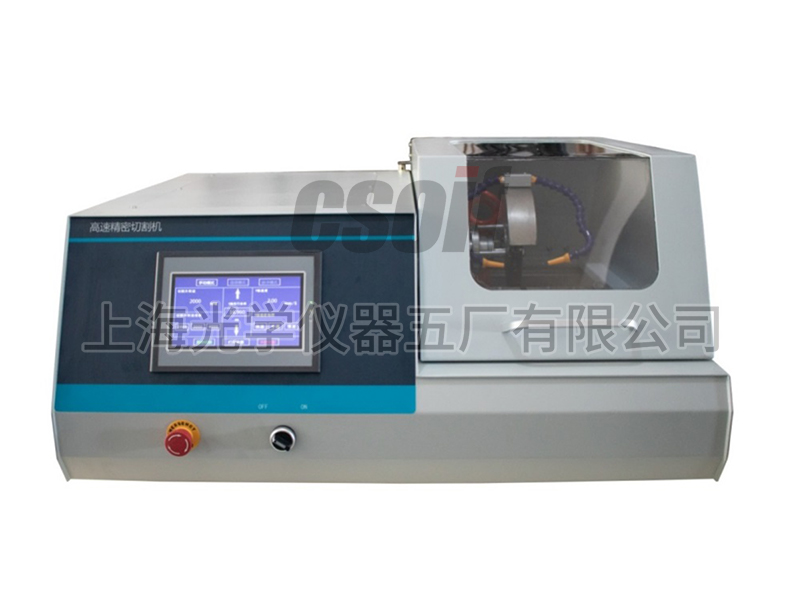

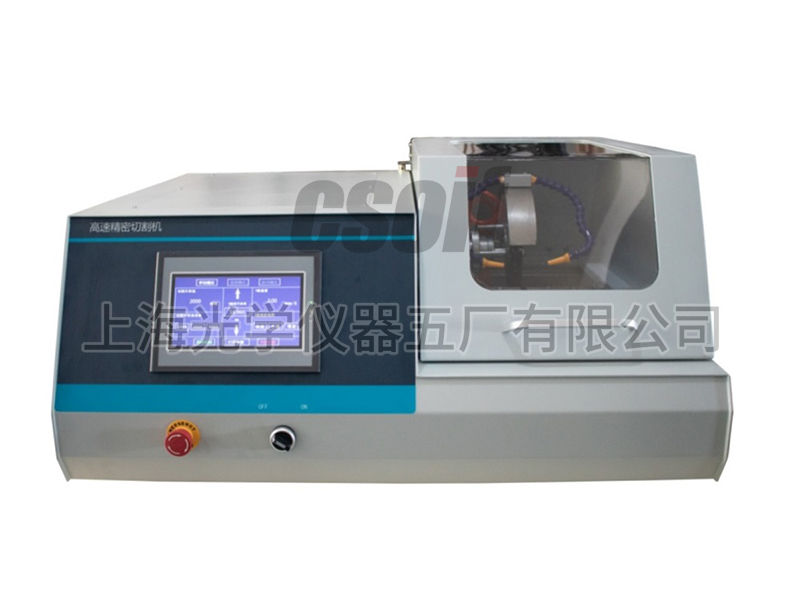

1.Product Overview

QG-200 high-speed precision cutting machine adopts touch screen and PLC control, stable performance, can display cutting parameters in real time; Y-axis automatic feed cutting, high positioning accuracy, wide speed range, strong cutting ability; The cutting chamber adopts a fully enclosed structure, transparent protective cover for observation during cutting; Equipped with circulating cooling system, the cut sample surface is bright, smooth, no burn; Especially suitable for metal, electronic components, ceramic materials, crystals, cemented carbide, rock and mineral, concrete, organic materials, biological materials (teeth, bone) and other materials for precision cutting without deformation, is the ideal choice for desktop automatic precision cutting.

2.Main functions and characteristics

1. Touch screen control and display, easy to operate, clear and intuitive.

2. PC material visible transparent window design, so that the cutting process at a glance.

3. Double protective junction and safety door switch design, making the cutting process safer.

4. Support stepless speed regulation or three speed regulation mode, speed regulation is more convenient.

5. With a variety of cutting modes to choose from, can meet the different cutting needs of users.

6. Multi-layer filter circulating water supply system, avoid cutting sample surface heat, save water consumption.

7. Equipped with fast fixture, the installation of the workpiece is more quick and convenient.

8. The fixture and workbench are made of aluminum alloy and stainless steel, which is more durable.

9. Can store more than 100 groups of cutting process parameters, easy to call quickly

10. Emergency stop button can be convenient and quick to stop the operation immediately, more safe

3. the main technical parameters

Input power supply | Single-phase AC220V, 50Hz |

Motor power | 1500W |

Cutting ability | Φ 60 mm |

Y-axis stroke | 260mm |

Cutting sheet specifications | 200 * 1.0 * Φ Φ 32 mm |

Cutting platform dimensions | 225×320mm |

Cutting disc RPM | 500-5000rpm |

Cutting jig | Quick jig |

Lateral clamping width | 225mm |

Clamping length lengthwise | 150mm |

Cutting method | Spindle Y direction automatic feed (automatic return after cutting), manual feed, pulse feed (automatic return after cutting) |

Feed speed | 0-180mm/min(adjust step size to 0.01mm) |

Mode of operation | Touch Screen |

Cooling method | Water cooling |

Equipment size | 830×810×410mm |

Weight | 130KG |

4. Configuration list

Product accessories | Units | Quantity | Remarks |

Tank | Taiwan | 1 | |

Diamond grinding wheel blade | slice | 1 | Φ 200 mm |

Wrench | the | 1 | # # 13 to 15 |

Wrench | the | 2 | 17 to 19 # # |

Allen wrench | the | 1 | 8mm |

Allen wrench | the | 1 | 6mm |

Technical files | 1 copy of product specification 1 copy of product certificate | ||