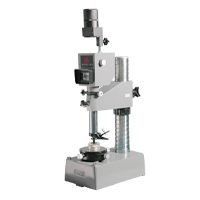

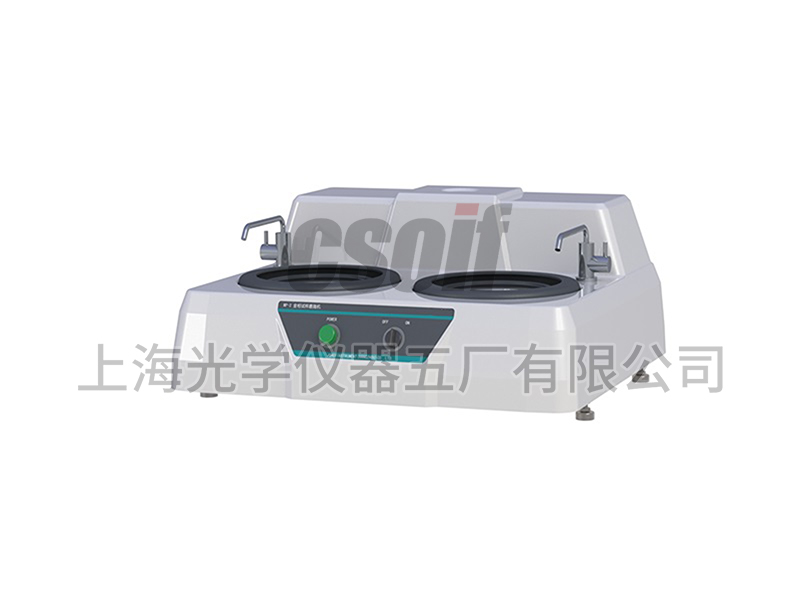

1.Product Introduction

In the process of metallographic sample preparation, sample grinding is an essential process. The grinding of the sample is generally divided into rough grinding and fine grinding two processes. The purpose of rough grinding is to obtain a flat surface, which is generally completed on the grinder, and there are still deep marks on the specimen surface. The purpose of fine grinding is to eliminate these wear marks, in order to obtain a flat and smooth grinding surface, and prepare for the next step of polishing. M-2 metallographic sample pre-grinding machine can be used for metallographic sample fine grinding, double disc design, two people can operate at the same time, the shell adopts the overall blister technology, novel appearance, with smooth rotation, low noise, easy operation, high work efficiency, and comes with cooling device, can be cooled in the grinding and polishing of the sample to prevent damage to the metallographic structure due to overheating of the sample. It is suitable for metallographic laboratory of factories, colleges and universities and scientific research institutions.

2.Technical parameters

Disk diameter | φ203mm (customizable φ230mm, φ250mm) | Input power | 370W |

Mill speed | 450r/min | Overall dimensions | 730 * 765 * 320 |

Input voltage | Single-phase 220V 50Hz | Heavy weight | 47Kg |

3.Parts list

Model number | Product name | Units | Quantity | |

M-2 | Metallographic sample pre-grinder | Taiwan | 1 | |

Product Accessories | Units | Quantity | Remarks | |

Millstone | a | 2 | It has been installed on the device | |

Water retainer | a | 2 | Already installed on the device | |

Pressing ring | a | 2 | Already installed on the device | |

Water sandpaper | zhang | 2 | Φ 203 mm | |

Water inlet pipe | The root | 1 | Φ 12 | |

Outlet pipe | The root | 1 | Φ 32 | |