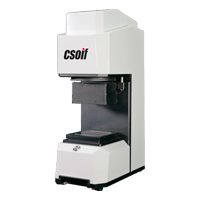

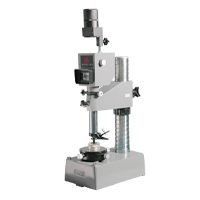

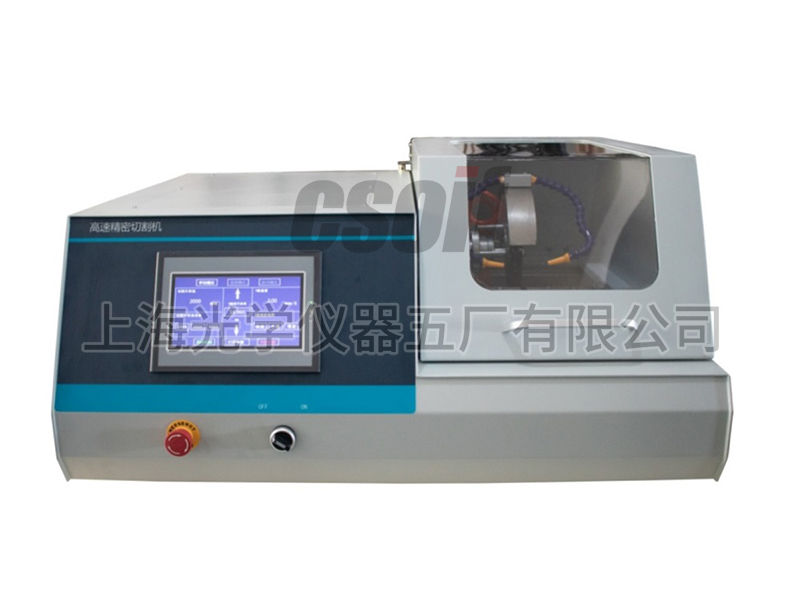

HBE-3000A electronic Brinell hardness tester adopts advanced electronic sensor loading technology. Through the closed-loop control system, the CPU controls the sensor to collect signals. The stepper motor automatically loads and unloads the test force, and can automatically compensate the test force to ensure that the force value is more accurate. Precise and more stable indication. After measuring the indentation through the eyepiece, the hardness value is directly obtained by pressing the button to input the indentation length, which improves the work efficiency. At the same time, it is equipped with an emergency stop device, which conforms to the EU CE safety standard, which has more reliable operability and safety, and has a high cost performance ratio. , widely used in factory workshops, colleges and universities, scientific research institutions, laboratories, etc.

1. Main functions and features:

1. Equipped with precision sensors and CPU microcomputer control system, which can automatically compensate, and the test results are accurate and stable;

2. With 10-level test force, it can test a wider range;

3. After measuring the indentation through the eyepiece, press the key to input the indentation length to directly obtain the hardness value, which improves work efficiency;

4. Equipped with a built-in printer, which can analyze and print the measurement data.

5. Equipped with high-performance stepper motor to automatically load and unload the test force, resulting in less noise during the test;

6. The shell is cast in one time, the structure is stable and not deformed, and it can work in a relatively harsh environment;

7. The surface is treated with car paint process, with strong scratching ability, and it is still as bright as new after many years of use;

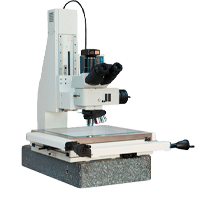

8. The machine can be equipped with Brinell image measurement software, which greatly improves work efficiency.

2. Main purpose and scope of application:

1. It is suitable for hardness tester testing of metal materials with large grains, which can reflect the comprehensive properties of materials;

2. Cast iron, steel, non-ferrous metals, alloys especially for softer metals, such as pure aluminum, lead, tin, etc.;

3. It can be used to measure the hardness of some non-metallic materials such as hard plastic and bakelite.

3. Main technical parameters:

| Product number | HBE-3000A |

| Brinell scale | HBW2.5/62.5、HBW2.5/187.5、HBW5/62.5、HBW5/125、HBW5/250、HBW5/750、 HBW10/100、HBW10/250、HBW10/500、HBW10/1000、HBW10/1500、HBW10/3000 |

| Test force | 62.5kgf(612.9N) 100kgf(980.7N) 125kgf(1226N) 187.5kgf(1839N) 250kgf(2452N) 500kgf(4903N) 750kgf(7355N) 1000kgf(8907N) 1500kgf(14710N) 3000kgf(29420N) |

| load control | Automatic (load/dwell/unload) |

| Maximum height of specimen | 220mm |

| smallest unit of measure | 0.005mm |

| dwell time | 0~60s |

| Hardness test range | 8~650HBW |

| total magnification | 20X |

| Executive standard | EN, ISO 6507, EN ISO 6506, ASTM E-384, ASTM E-10-08, ASTM E-384 GB/T231.2,JJG150 |

| Indenter-outer wall distance | 135mm |

| Indenter-upper wall distance | 55mm(The distance from the indenter to the upper machine wall can be increased by customizing the indenter) |

| Hardness reading | After measuring the indentation through the eyepiece, press the key to input the indentation length to directly obtain the hardness value. |

| data output | Built-in printer, print content: test conditions, number of measurements, average value, maximum value, minimum value, maximum error, etc. |

| power supply | AC220+5%,50~60Hz |

| Dimensions (mm) | 520*210*745mm |

| Host weight | About 120kg |

4. Attachments:

| name | quantity |

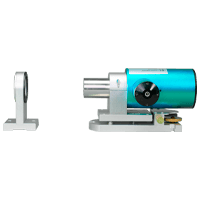

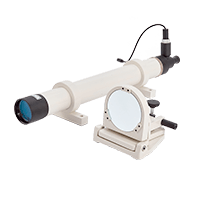

| Measuring microscope | 1 set |

| Standard hardness block | 3 pieces |

| power cable | 1 |

| fuse | 2 |

| Carbide ball indenter with diameter of 2.5, 5, 10mm | 1 each |

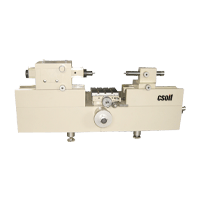

| Large, medium and V-shaped test benches | 1 each |

| Product certificate, product instruction manual | 1 each |

| dust cover | 1 |