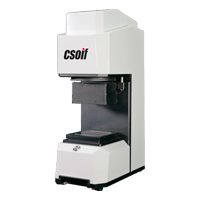

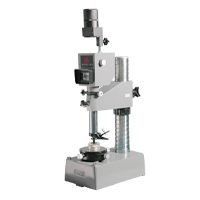

I. Features

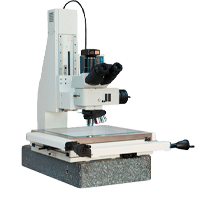

The automatic microhardness tester is mainly used to measure tiny, thin specimens, and brittle hardware. It can be widely used in various metals (ferrous metals, non-ferrous metals, castings, alloy materials) by selecting various accessories or upgrading various structures. etc.), metal structure, metal surface processing layer, electroplating layer, hardened layer (oxidation, various infiltration layers, coating layer), heat treatment specimens, carbonized specimens, quenched specimens, tiny parts of phase inclusions, glass, agate , artificial gemstones, ceramics and other brittle and hard non-metallic materials testing. It is especially suitable for mass measurement of the hardness gradient distribution curve of workpieces, and hardness testing of specified parts.

Second, technical parameters

| Parameter name | parameter data | ||||

| Microhardness scale | HV0.01 | HV0.025 | HV0.05 | HV0.1 | |

| HV0.2 | HV0.3 | HV0.5 | HV1 | ||

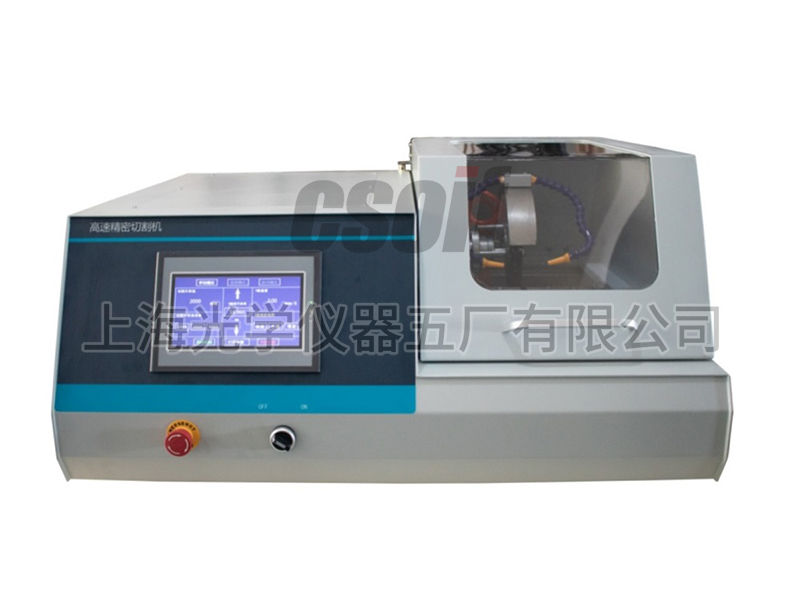

| display | 7 inch LCD touch screen | ||||

| Test force (gf) | 10, 25, 50, 100, 200, 300, 500, 1000 | ||||

| loading controls | auto (load/hold/unload) | ||||

| Test force holding time(s) | 5~60 | ||||

| Test force selection | External force selection knob, the test force is automatically displayed on the 7-inch LCD touch screen | ||||

| objective magnification | 10×, 40× | ||||

| light channel | Dual optical channels (eyepiece and CCD camera channel) | ||||

Optics (dual optical channel, no switching required) | 1. Automatic numeric encoder; 2. Total magnification (μm): 100×(observation), 400×(measurement ); 3. Measurement range (μm): 200;4. Resolution (μm) : 0.01 | ||||

| Hardness measurement range | (5-3000)HV | ||||

| Data output (optional) | Built-in printer, test data can also be output to U disk via USB for saving and analysis | ||||

| Maximum specimen height (mm) | 110 | ||||

| Maximum width of specimen (mm) | 120 distance from the center line of the indenter to the machine wall) | ||||

| Supply Voltage | AC220V/50HZ | ||||

| Weight(kg) | 40 | ||||