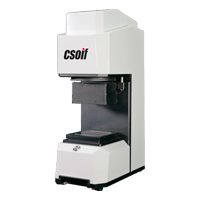

I. UsePurpose

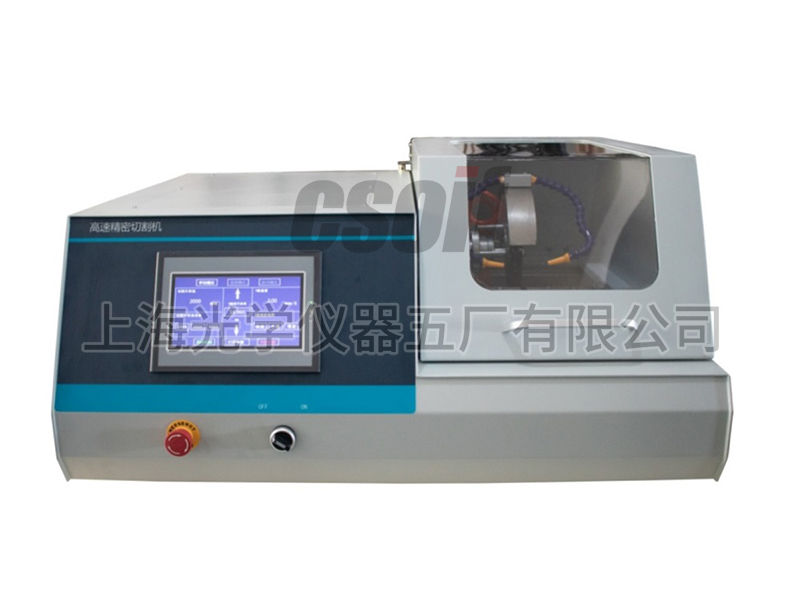

The touch screen digital display Blowwell hardness tester has novel appearance, complete functions, convenient operation, clear and intuitive display, and stable performance. It is a high-tech product integrating light, machine and electricity. Test method test, a multi-functional hardness tester with twenty-three measuring scales, which can meet various hardness testing needs. It has the characteristics of high test accuracy, simple operation, high sensitivity, convenient use and stable indication. Equipped with a built-in printer, and an optional RS232 data cable can be connected to a computer through a hyperterminal, or the measurement report can be exported from a U disk. Large-screen LCD touch screen display interface, rich display content, easy to operate. Determination of Brinell, Vickers and Rockwell hardness of ferrous metals, non-ferrous metals and hard alloys: Brinell hardness of castings, annealed steel, normalized steel, non-ferrous metals and soft alloys; Rockwell hardness of quenched, quenched and tempered heat-treated materials Hardness; Vickers hardness of nitrided layer, ceramics, sheet, metal sheet, electroplating layer, tiny parts;

2. Features

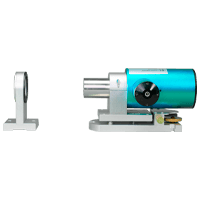

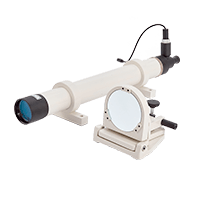

1. The optical system designed by the senior optical engineer not only has clear images, but also can be used as a simple microscope, with adjustable brightness, comfortable vision, and long-term operation is not easy to fatigue;

2. The 7-inch LCD touch screen can directly display the hardness value, conversion hardness, test method, test force, brightness, dwell time, measurement times, statistical data, and test time, etc. The test process is intuitive and clear; 3. ;The system has its own calibration function, which can manually adjust the input error to calibrate the instrument;

4. When testing the surface, it is automatically corrected according to the standard surface radius;

5. Optical system brightness adjustable range: 0-100;

6. It can store 100 sets of test data, you can check the test data at any time, you can also delete the current data or clear all the test data;

7. The unit of test force can be manually converted to each other, and the conversion unit is: (Kgf, N)

8. Can display at the same time: maximum value, minimum value, average value, test times, test block name (the test block number can be input);

9. The main interface can display 4 conversion scales at the same time, and can switch: National Standard (GB), American Standard (ASTM) and International (ISO) standard, a total of 21 measurement scales can be converted: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HK, HBW, HS, HBS, HV, Rm (tensile strength), MPa (compression strength);

10. With the diagonal length memory function, the diagonal length will be automatically memorized after the machine is turned off, and it will be measured directly after the machine is turned on, without the need for secondary reset.

11. The upper and lower limits of the measurement range can be set, displayed on the main measurement interface, and the unqualified value will automatically prompt an alarm;

12. The operating system has 13 languages, which can be switched at will: Chinese, English, Russian, German, French, Spanish, Portuguese, Turkish, Czech, Japanese, Korean, Thai, Vietnamese;

13. It has three test methods of Brinell, Rockwell and Vickers, and seven test force, which can meet various hardness test requirements;

14. Equipped with a built-in printer, and the test data can also be output to a U disk via USB for storage and analysis;

15. The structure of the casting shell is stable and not deformed at one time, the pure white car paint is of high grade, and the scratch resistance is strong, and it is still bright as new after many years of use;

16. Our company has the ability to develop, design and produce by ourselves. Our machines provide parts replacement and maintenance and upgrade services for life;

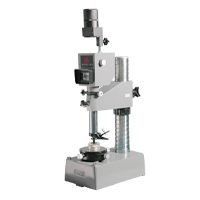

Three, technical parameters

| Product number | SHBRV-187.5F | ||||

| Brinell scale | HB1/30, HB2.5/31.25, HB2.5/62.5, HB2.5/187.5, HB5/62.5, HB10/100 | ||||

| Rockwell Scale | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HEP, HRR, HRS, HRV | ||||

| Vickers Scale | HV30, HV100 | ||||

| Test force | Rockwell test force: 60, 100, 150Kgf (588, 980, 1471N) | ||||

| Brinell test force: 30, 31.25, 62.5, 100, 187.5Kgf (294.2, 306.5, 612.9, 980.7, 1839N) | |||||

| Vickers test force: 30, 100Kgf (294.2, 980.7N) | |||||

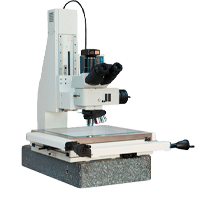

| gain | Brinell: 37.5×, Vickers: 75× | ||||

| Maximum height of specimen | Rockwell 230mm Vickers Brinell 180mm | ||||

| Indenter-outer wall distance | 165mm | ||||

| Hardness test range | Rockwell: 20-88HRA, 20-100HRB, 20-70HRC Brinell: 3.18~653HBW Vickers: 10-3000HV | ||||

| Hardness reading | Automatic calculation | ||||

| power supply | AC220+5%, 50~60Hz | ||||

| Dimensions (mm) | 550×200×720mm | ||||

| Host weight | About 85kg | ||||

Instrument standard configuration

| name | quantity | name | quantity | ||

| Rockwell 1/16" steel ball indenter | 1 | Rockwell diamond indenter | 1 | ||

| Brinell 2.5mm indenter | 1 | Brinell 5mm indenter | 1 | ||

| Vickers diamond indenter | 1 | Standard Rockwell hardness block | 5 pieces | ||

| Standard Brinell hardness block | 1 block | Standard Vickers hardness block | 1 block | ||

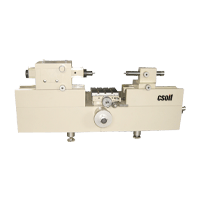

| Medium and V-shaped test bench | 1 each | Sliding test stand | 1 | ||

| power cable | 1 | dust cover | 1 | ||