1. Purpose

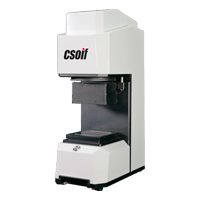

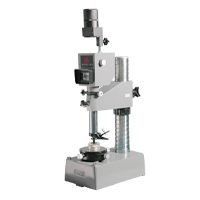

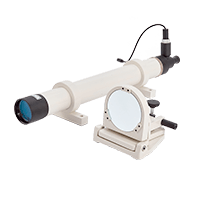

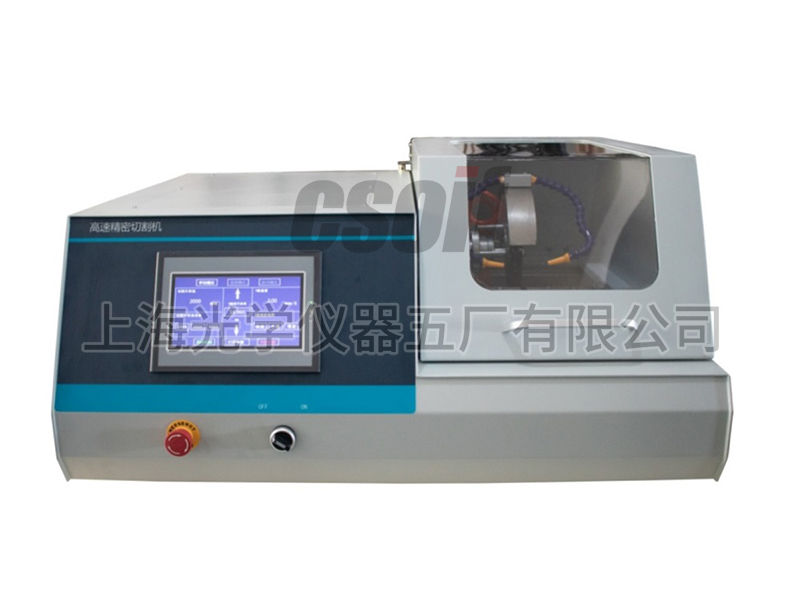

Automatic turret microscope The hardness tester is a high-tech product of opto-mechanical integration. The hardness tester has a novel shape, good reliability, operability and repeatability, and is an ideal product for testing microhardness. The machine adopts C language programming, high magnification optical measurement system and optical dual-channel structure, and new technologies such as photoelectric and photocouple sensing. Through key operation, the length of the indentation to be measured can be input on the key, and the hardness value, conversion scale, test force, test force holding time and measurement times can be displayed on the screen. Applicable to steel, non-ferrous metals, metal foil, cemented carbide, sheet metal, microstructure; carburizing, Nitriding and decarburization layer,Surface hardening layer, electroplating layer, coating; glass, wafer, ceramic material.

II. Features

The optical system designed by the senior optical engineer not only has clear images, but also can be used as a simple microscope with adjustable brightness and comfortable vision , It is not easy to be fatigued after long-term operation; the hardness value, conversion hardness, test method, test force, dwell time, measurement times, and the test process are intuitive and clear on the industrial display screen; the cast aluminum shell is formed at one time, and the structure is stable and not deformed , High-grade pure white car paint, strong anti-scratch ability, and it is still bright as new after many years of use; our company has the ability to develop, design, produce and process by ourselves, and our machines provide parts replacement and maintenance upgrade services for life; HV-1000Z model Realizable: The position switching of observation-test-measurement is completed by automatic turret.

Three, technical parameters

| Parameter name | parameter data | |||||

| Microhardness scale | HV0.01,HV0.025,HV0.05,HV0.1,HV0.2,HV0.3,HV0 .5,HV1 | |||||

| display | hold time (seconds), hardness value | |||||

| Test force (gf) | 10, 25, 50, 100, 200, 300, 500, 1000 | |||||

| loading controls | Automatic (load/hold/unload) | |||||

| Test force holding time(s) | 5~60 | |||||

| Trial force selection | External force selection knob, the test force is automatically displayed on the screen | |||||

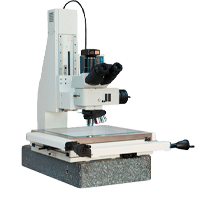

| objective magnification | 10×, 40× | |||||

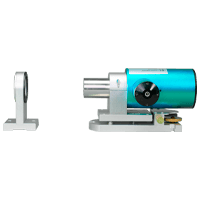

| optics | 1. Manual micrometer eyepiece; 2. Total magnification (μm): 100×(observation), 400×(measurement); 3. Measurement range (μm): 200 4. Resolution (μm): 0.25 | |||||

| Hardness measurement range | (5-3000)HV | |||||

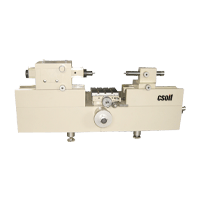

| XY stage | Size(mm):100×100 Stroke Range(mm):25×25 Minimum reading (mm): 0.01 | |||||

| Maximum specimen height (mm) | 110 | |||||

| Maximum width of specimen (mm) | 85 (distance from indenter centerline to machine wall) | |||||

| Supply Voltage | AC220V/50HZ | |||||

| Weight(kg) | 35 | |||||

| Dimensions(mm) | 540×200×530 | |||||

Standard configuration

| host | 1 set | Stand, weight, microscope accessory case | 1 |

| weights | 6pcs | weight bar | 1 |

| cross table | 1 | sheet holder | 1 |

| Flat clamp table | 1 | filament holder | 1 |

| level | 1 | screw | 2 pieces |

| leveling screw | 4pcs | External power cord | 1 root |

| 10X micrometer eyepieces | 1pc | Micro Vickers hardness block | 2 blocks (HV1, HV0.2 each) |

| fuse (1A) | 2 | Product Certificate | 1 serving |

| Product Instruction Manual | 1 serving | dust cover | 1pc |