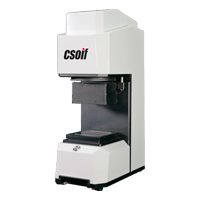

I. Purpose

SHL-150 Portable Leeb Hardness Tester, which can directly measure Rockwell (HRC, HRB), Leeb (HL) , Brinell (HB), Vickers (HV), Shore (HS) hardness values. In line with international standards and the "Leeb hardness tester technical conditions ZBN71010-1990" issued by the Ministry of Machinery Industry, "metal Leeb hardness test method" issued by the State Bureau of Quality and Technical Supervision "GB/T 17394-1998", Leeb hardness Standard JB/T9378-2001 and other standards.

SHL-150 one host can be equipped with 7 different impact devices, automatically identify the type of impact device, no need to renew when replacing calibration. Ultra-low power consumption design, using high-performance lithium battery to achieve long working and standby time, more compact and flexible design to improve the flexibility of use.

According to the principle of Leeb hardness measurement, it can test a variety of metal materials with high precision. Support "forged steel (Steel)" material, when testing "forged steel" samples with D/DC impact device, the HB value can be directly read without manual look-up. It is convenient to switch to all hardness scales (HL, HB, HRB, HRC, HRA, HV, HS), and convert the measured values of each hardness scale in parallel.

2. Features

display: Full Chinese display, menu operation , the operation is simple and convenient. whiteBacklit display for easy use in dark environments.

Data communication: with USB interface, a variety of communication methods to meet the individual needs of different users.

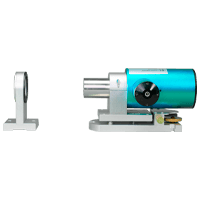

Measuring function: One host can be equipped with 7 different impact devices, no need to re-calibrate when replacing, automatically recognize impact Device type.

Data storage: can store 48~350 groups (32~1 impact times) single measurement value, average value, measurement Date, impact direction, frequency, material, hardness scale and other information.

Alarm output: The upper and lower limits of the hardness value can be set in advance, and an automatic alarm will be sent out of the range, which is convenient for users to test in batches.

Calibration: Indication software calibration function.

Battery: Built-in high-performance lithium battery and charging control circuit, with long working time and standby time. The liquid crystal displays the battery symbol and displays the current remaining power in real time.

Software: According to the requirements of users, it can be equipped with computer software, which has more powerful functions and meets Higher requirements for quality assurance activities and management.

III. Technical parameters

| Parameter name | parameter data | ||

| measurement range | HLD(170~960)HLD | ||

| measurement direction | 360° | ||

| hardness scale | Rich, Brinell, Rockwell A, Rockwell B, Rockwell C, Vickers, Shaw span> | ||

| display | LCD,128×64 Graphic dot matrix LCD | ||

| Data Storage | 48~350 group (32~1 shocks) | ||

| The upper and lower limit setting range | Same measurement range | ||

| rechargeable power source | 5VDC, 220VAC | ||

| Charging time | 2~3.5 hours | ||

| battery | 3.7V, (1400mAh) lithium battery | ||

| ambient temperature | 0~40℃ | ||

| Storage temperature | -25~70℃ | ||

| continuous working hours | about 100 hours (without backlight) | ||

| Communication interface standard | USB | ||

| Dimensions | 179×77×35mm(host) | ||

| weight | about 1 75g (host) | ||

Indication error and indication repeatability

| serial number | Shock device type | Standard Leeb hardness value | Indication error | Indication repeatability |

| 1 | D | 760±30HLD 530±40HLD | ±5 HLD ±8 HLD | 5 HLD 8 HLD |

| 2 | DC | 760±30HLDC 530±40HLDC | ±5 HLDC ±8 HLDC | 5 HLD 8 HLD |

| 3 | DL | 878±30HLDL 736±40HLDL | ±10 HLDL | 10 HLDL |

| 4 | D+15 | 766±30HLD+15 544±40HLD+15 | ±10 HLD+12 | 10 HLD+12 |

| 5 | G | 590±40HLG 500±40HLG | ±10 HLG | 10 HLG |

| 6 | E | 725±30HLE 508±40HLE | ±10 HLE | 10 HLE |

| 7 | C | 822±30HLC 590±40HLC | ±10 HLC | 10 HLC |

Standard configuration

Instrument host 1 set

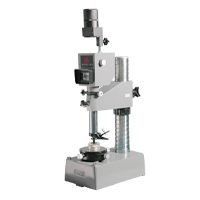

D-type impact device 1 piece

1 small support ring

Nylon brush (I) 1pc

High value Leeb hardness block 1 block

Charger 1pc

Communication cable 1 piece