use

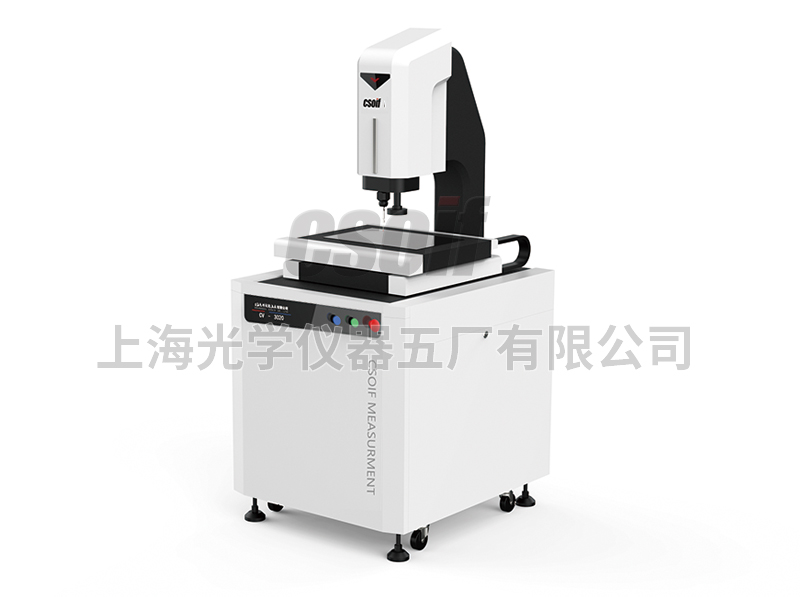

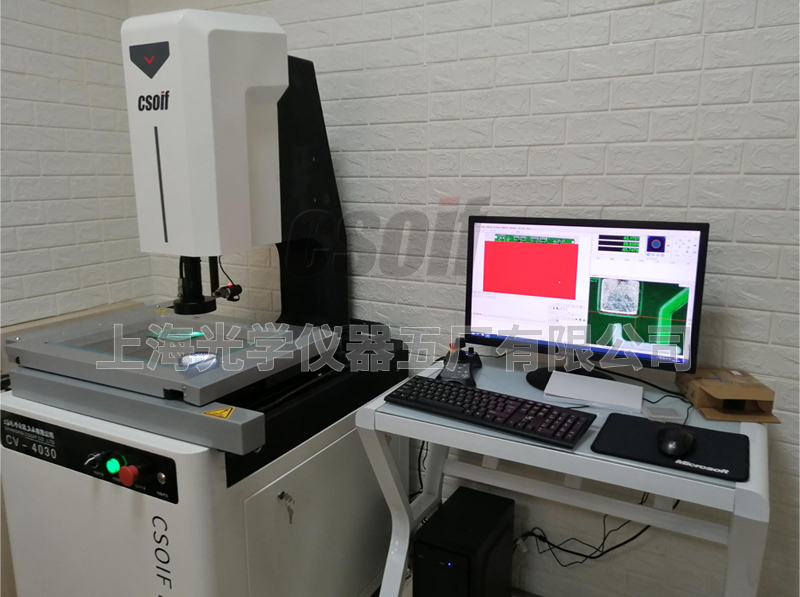

Can be used to measure LCD, FPC, PCB, circuit boards, hardware, stamping parts, screws, springs, clocks, watches, instruments, connectors (connectors, terminals), threads, gears, cams, radius templates, thread templates, Wire and cable, knives, screen, test screen, cement screen, screen plate (steel mesh, SMT template), etc.

Features

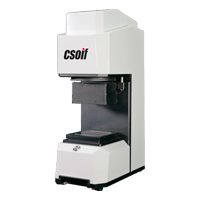

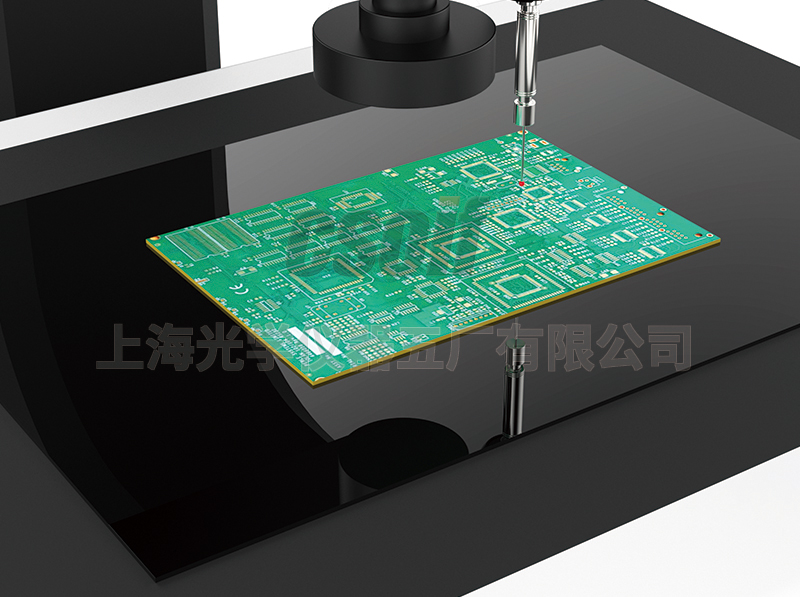

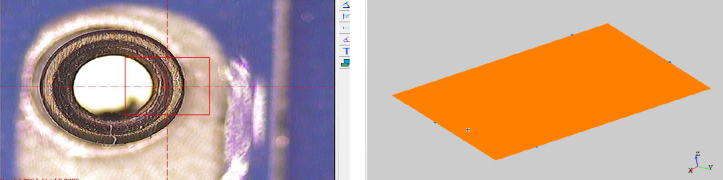

1. The CV automatic image measuring instrument series in the CSOIF series has the AF automatic focusing function. A three-dimensional probe can be added to any imager to realize two-dimensional and three-dimensional measurement and inspection coaxially.

2. The metal four-layer workbench and multiple failure processes ensure long-term stability. Equipped with fixture hole; programmable 8-zone annular surface light source, LED parallel contour light source, coaxial light source optional; automatic focus height measurement, can be installed with various RENISHAW contact probes (PH6, MH201, MCP, etc.), point laser Scan the probe.

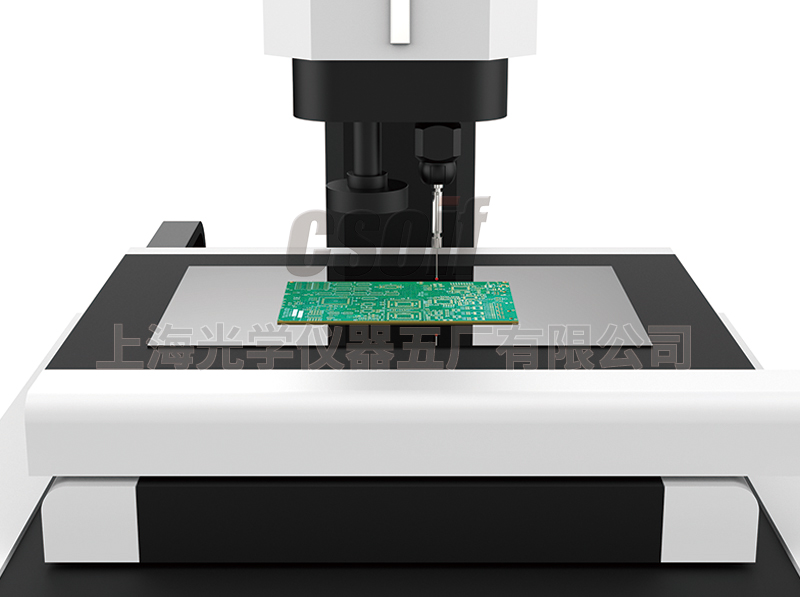

3. The CV automatic imager series in the CSOIF series is based on 1.3 million industrial cameras, a dedicated DSP post-processing camera for measuring image contrast, and comes standard with the company's self-developed AZ automatic focusing lens. Combined into a set of high-performance professional image measurement system.

4. The CV automatic imager series in the CSOIF series uses 00-grade granite as the base + column, and cooperates with a high-precision workbench to ensure portability, while the frame is stable, sensitive and reliable, and accurate in positioning. > XY axis precision ball guide, precision screw drive system, Z axis adopts Shangyin linear guide.

5. Single-field scanning glass grating ruler with novel professional technology; metal patch grating can also be selected. Fully automatic measurement, three-axis CNC closed-loop control system. Surface compensation, 11 software error corrections; powerful composite measurement software.

The main parameters

| model | CV3020 | CV4030 | CV5040 | ||||

| Measuring range (mm) | 300X200X200 | 400X300X200 | 500X400X200 | ||||

Dimensions (mm) | Instrument size | 650*810*1560 | 750*880*1660 | 850*980*1660 | |||

| Computer Desk | 800*600*750 | 800*600*750 | 800*600*750 | ||||

| Weight (kg) | 290 | 420 | 470 | ||||

Indication accuracy um optics | X,Y | ≦2.0+L/200(um) | ≦2.0+L/200(um) | ≦2.5+L/200(um) | |||

| Other probes | contact | Optional various fixed touch probes | |||||

| Laser class | Optional spot laser and white light confocal head | ||||||

| Maximum load of glass table (kg) | 15 | 15 | 15 | ||||

| grating scale standard scale resolution | Glass grating ruler, standard 0.1um (optional higher precision) | ||||||

| Control System | British four-axis special controller with three-axis screw drive | ||||||

| motor | Servo Motors for Custom Instruments | ||||||

| Lighting source | 8-zone LED ring light source, each segment is independently controlled / LED parallel bottom light, programmable control | ||||||

| Objective lens (X) standard | 0.6X-5.0X manual freeze-frame zoom lens, image magnification 28X-175X | ||||||

| Objective lens (X) optional | It can be selected according to the magnification or reduction ratio of the workpiece to be measured | ||||||

| CCD (standard) | 130W digital camera | ||||||

| working environment | Temperature 20℃±2℃, temperature change <2℃/hr, humidity 20% to 80% | ||||||

| Operating Voltage | 220V+10%,50HZ-60HZ | ||||||

| Acceptance method | Acceptance with glass line ruler | ||||||