I. Purpose

Hardness tester control: The system provides serial communication to control the operation of the hardness tester, such as rotating the objective lens, loading, setting the holding time, adjusting the light brightness, adjusting the test force feedback, etc.;

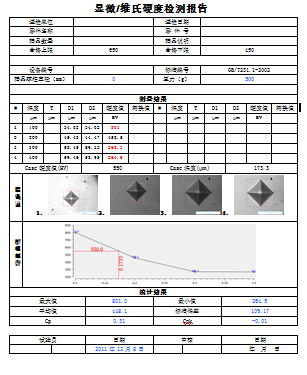

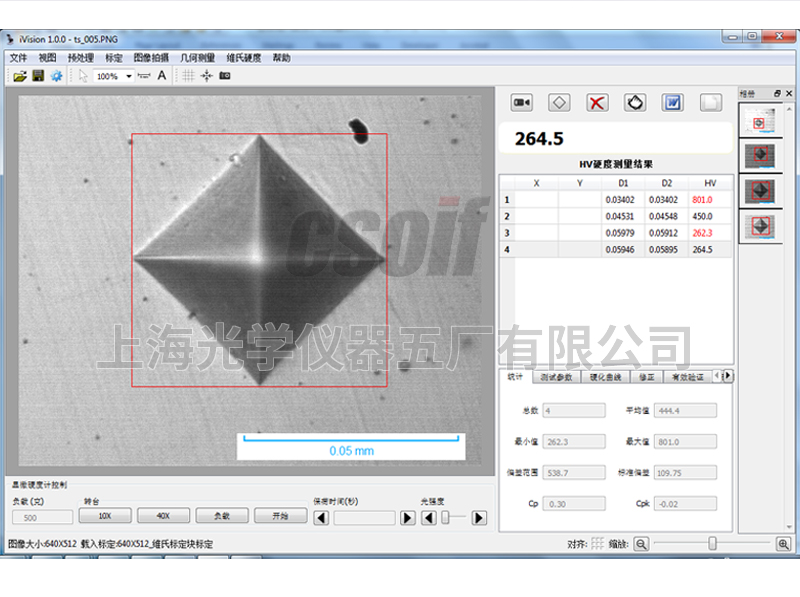

Automatic measurement: The system automatically measures the indentation, automatically draws the hardening curve, and updates the statistical results, etc.;

Manual measurement: The system provides manual measurement, including four-point measurement and diagonal measurement;

Hardness value conversion, correction, effective verification: The system can simultaneously convert the measured micro-Vickers hardness value to other hardness scales such as HB, HR, etc.; it can measure the value of spherical cylindrical samples Correction; valid verification of sample measurement values;

Data statistics: Automatically calculate the average value, variance, Cp, Cpk and other statistical values of the measured hardness, and can choose to save automatically;

Data storage: Single measurement data and images can be saved in a file for later recall, and can be automatically saved;

Test report: Automatically generate WORD or EXCEL document report; the user can customize the report format; the standard format includes each individual hardness measurement value, statistical value, indentation image, and hardening curve, etc.;

Knoop hardness: can be set to Knoop hardness measurement;

Fracture toughness: can be set to measure indentation fracture toughness;

Other functions: Contain all the functions of the iVision-PM microscopic image processing and measurement system, including image capture, calibration, image processing, geometric measurement, document annotation, album management, and fixed size printing, etc. ;

2. Features

Manual modification: After automatic or manual measurement, you can easily drag and drop manually with the mouse to modify, measured values and statistical results will be updated automatically.